- April 22, 2022

- No Comment

Press Brakes – Why you need a 7 Axis

Presented by Complete Machine Tools

There are 4 common but crucial factors that dictate the potential for success and growth of every sheet metal fabrication workshop in the world…

Consistency, Accuracy, Efficiency and Speed.

With the ever present march of time and technology, and the veritable abundance of machinery and technology out there to choose from in order for businesses to stay ahead of the game, the difficult part these days is deciphering what is truly worth investing in and what is simply the same old tech with a new paint job. It’s so important for anyone in business to understand the difference between something that is just new, and something that is a genuine improvement on the way things have been, and are currently being done. Something that provides that edge to ensure that we aren’t falling behind, because in today’s day and age, falling behind could very well mean being left behind.

New advancements in the development of hybrid machine tools, incorporating both servo and hydraulic driven systems, has resulted in a wave of incredibly intelligent machinery for the sheet metal and steel fabrication sector globally. This is great news for business owners in the industry as it is helping to counter the rising cost of freight and raw materials by reducing waste through the minimisation of errors during fabrication.

One particular set of machinery benefitting from these advancements is the Press Brake, and these machines mean business.

Enter the new generation of 7 Axis, CNC controlled Press Brakes. These machines tick all 4 boxes of our common but crucial checklist.

Consistency: The advanced levels of automation delivered by the new generation of 7 Axis Press Brakes, ensure that time and time again your bends are inline with set parameters. Dramatically decreasing the chance for potential human error, resulting in increased production levels and a more consistent end result on the product. The Industry 4.0 ready, AccurlCMT EuroMaster series for example, utilises a combination of both electric servo motor and hydraulic drive systems throughout their range. Most notably, the servo motor driven backstops offer previously unseen levels of reliability and performance that eliminate the need for manual intervention for repositioning of the material. Coupled with the quality of their Italian manufactured back gauge fingers, this provides vastly superior accuracy.

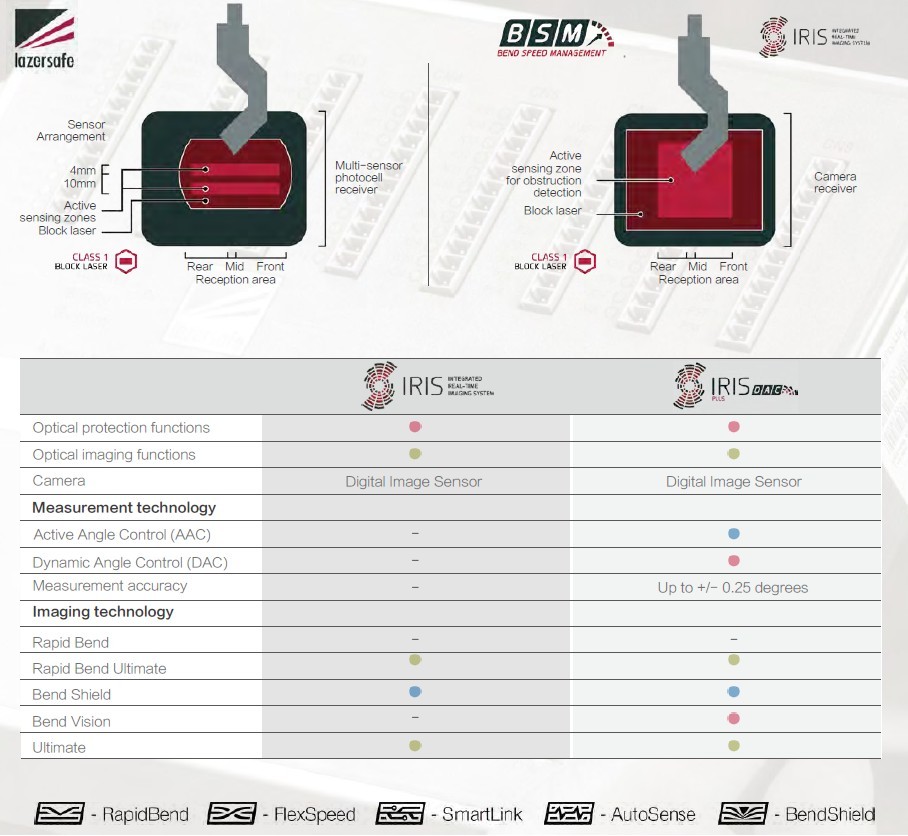

Accuracy: Automation means accuracy. Now don’t get me wrong, there is no denying the benefits and the necessity of experienced individuals who have developed their skills over decades. However, that hands on knowledge combined with the ability to automate the processes and parameters needed for the day to day manufacturing of your products is an extremely powerful advantage to have. The AccurlCMT EuroMaster series provides this advantage through the Delem CNC controller, offering complete automation of almost every aspect of the machine. Once entered into the controller, all axis are automatically adjusted to accommodate the required dimensions. Ensuring superior accuracy compared to conventional machines. For added safety the AccurlCMT EuroMaster series come standard with the Australian made laser guarding systems from Lasersafe as shown below, and can also be optioned up to include automatic laser angle measurement and correction to even further increase accuracy. For additional piece of mind as well, the CNC controlled, automatic crowning in the bed, eliminates the bowing effect from occurring in the middle of the machine.

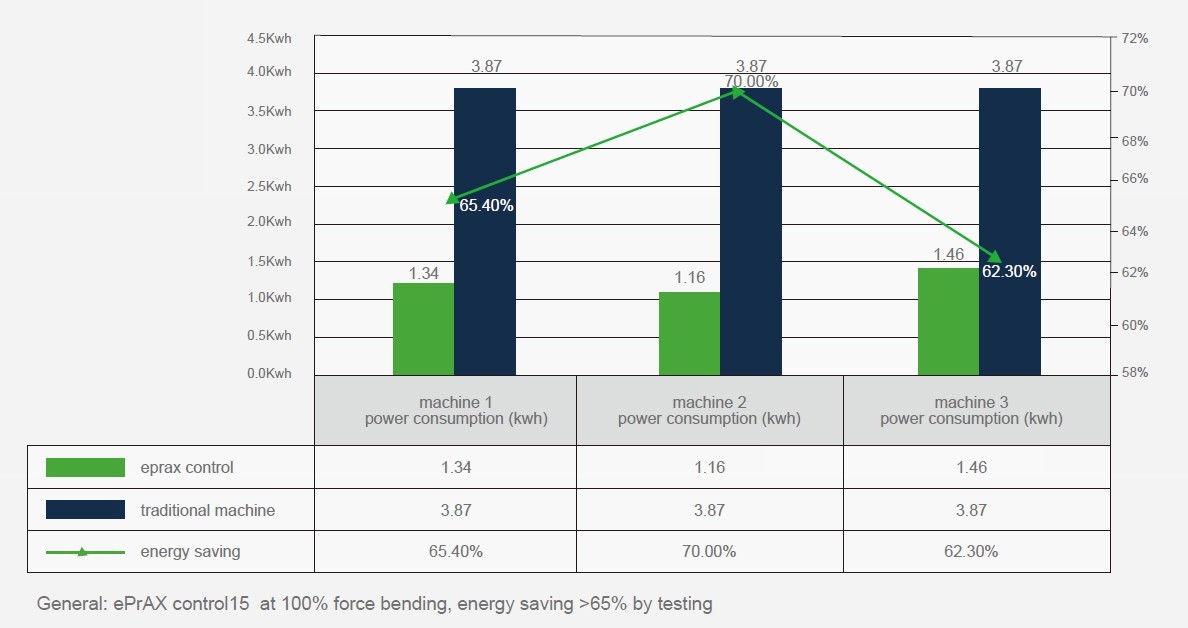

Efficiency: A more reliable machine is a more efficient machine. Reducing down time and energy consumption is at the forefront of machine tool technology, and being industry 4.0 ready is crucial for those looking to maximise production as it makes the monitoring of the machines operation and status far more accessible, and the servo/hydraulic hybrid generation of seven axis press brakes, allows for greatly improved energy efficiency and oil consumption. The ePrAX® control hybrid system employed in the industry 4.0 ready AccurlCMT EuroMaster series, is an innovative servo drive that reduces energy consumption by up to 70% and the brushless motor allows for precise control over the movement of the ram, resulting in using a minimum amount of oil and energy. Shown below are the ePrAX® system results on energy consumption when compared to a conventional 135ton Press Brake. The difference is substantial.

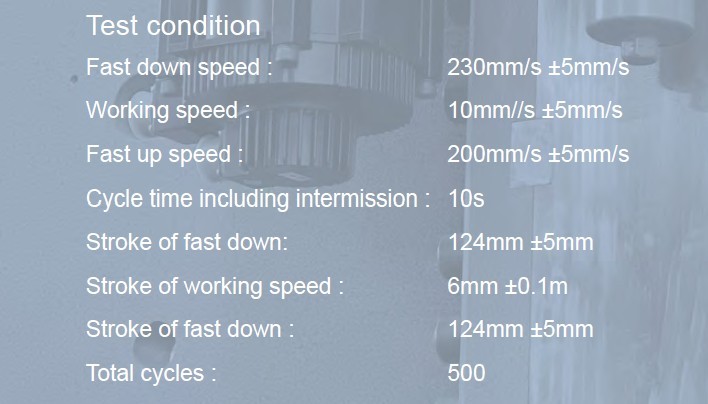

Speed: Simplicity reduces errors and means less need for corrections, meaning faster production times. Getting those jobs out the door and to the client as fast as possible without compromising on quality. This new generation of 7 axis press brakes are the simplest to operate yet and the working operation speeds of the machines save valuable time. To provide a comparison, under test conditions the AccurlCMT EuroMaster series delivered the incredible results shown in the image below.

The most valuable commodity every business owner and in fact every person on the planet possesses is time. The machinery supplied by Complete Machine Tools and especially the AccurlCMT EuroMaster, 7 Axis series Press Brakes, are designed to give you back just that, TIME!, Through next generation automation and superior componentry and tooling.

The highly flexible machine is the latest development in the AccurlCMT press brake range. Delivering new technical innovations in combination with the already well proven technology and know-how to provide a level of product and service that that can be relied upon to deliver superior Consistency, Accuracy, Efficiency and Speed.

Ticking all of the boxes in our common but crucial checklist, the Seven Axis press brake is a machine that stands out as a (pardon the use of a cliché phrase) complete no brainer, when it comes to deciding on an upgrade of your old machine or to purchasing the new equipment that your business needs in order to meet the increasing demand the industry is seeing, particularly in Australia.

The best part…. they don’t break the bank.

The pricing offered on this generation of press brakes is extremely reasonable and well worth the investment, especially when compared to their 5 axis counterparts as the difference in price between respective size machines is quite low. Considering the increase in productivity and reduction in running costs these machines are capable of delivering, the Seven Axis series of press brakes is an all round smarter way to go, as it enables the user to potentially take on additional and possibly even larger jobs they otherwise wouldn’t have been able to accept and the AccurlCMT EuroMaster series 7 Axis range is no exception as they are extremely affordable.

As with any machine you purchase, warranty should be standard, and follow up service and support is crucial. At Complete Machine Tools Australia, all AccurlCMT EuroMaster series Press Brakes come with a 24 month warranty on parts and a 12 month warranty on labour, and we can not stress enough the importance of knowing that the technicians providing the support for the machinery that we supply, are the same technicians that assemble the machine and prepare it for delivery. Providing the piece of mind that comes with knowing your getting someone that knows the machine inside out if you need them.

So if you are in the market for a new Press Brake, and have been tossing and turning over the decision on which way to go. Get ahead of the game and move with the march of time and technology. The Seven Axis machine is the way to go to make sure you aren’t left behind.