Gardner Engineering 4 Tine Hydraulic Grab - Heavy Duty - Hardox steel construction - Protected Hyd Cylinder - Large and powerful single Hyd cylinder - Australian made - 12 months warrantyGardner Engineering Australia is ....

M nart high-speed shredders have been developed to meet the needs of compost platforms, waste sites, urban organic waste valorisation centres, agricultural exploit sites, landscapists and other green waste professionals. HIGH WORKING CAPACITY The feeding hoppers are designed to be loaded by loaders, tractors, cranes, etc. The rotors are large and heavy. Small and medium MENART shredders are ideal for shredding large amounts of waste in a short time. ROBUST AND EASY TO USE MENART swinging-hammer shredders can shred any mix of green waste grass, leaves, branches, wood, etc. , pallets, ....

TB-2000e towed road broom, 2009 model, 2500 hrs, powered by a 3cyl Kubota diesel engine. comes with remote control , hyd O R barkes , approx 70 broom condition, operates good, well maintained by previous council. deliver....

Sweeps and Screens fits CAT D8T Bulldozer Features Designed to accept OEM parts Painted to match OEM equipment black One Year Warranty Including Original style of Sweeps Side Screens Door Screens Rear Screens Roof Comple....

The EC600 Series gives you the most height in an electric powered boom lift and over 13.10 m 43 ft of horizontal outreach. Reach up to 18.28 m 60 ft with the EC600 Series, which is available in electric or hybrid power a....

Antraquip AQ- 5 for sale or hire. Good condition used. Comes with new pins and a crate of spare teeth. Finance available as well as hire solutions. the AQ-5 hydraulic drum cutter is an excellent option for carriers in the 40-80 ton weight class. The combination of power, and robust design of the transmission and cutting drums, the AQ-5 is capable of cutting many types of hard rock with excellent efficiency.....

Bullant 19ft Scissor Lift Plant Trailer Drop axle for low loading and Low centre of gravity Superior towing stability Hot Dip Galvanised for rust protection 4 wheel disc brakes with a hydraulic brake electric brake optional extra Narva LED Lights winch not included ....

Unused Grapple Bucket to Suit Skid Steer to suit Skid Steer 1828mm wide Operating pressure 17-21MPa Dual Ram Approximate Shipping dimensions 1930mm L x 1100mm W. x 790mm H Weight 275Kgs....

4.6 m working height 500 kg SWL capacity 2 speed winch Travels through doorway Legs fold for compact storage Adjustable steering level handle PLATFORM HEIGHT 5.00m STOWED HEIGHT 1.95m WIDTH 0.80m WEIGHT 157kg LIFT CAPAC....

Brand New 2023 Multipac 516H Multi Tyre Roller- 11-24 Tonne Fully Hydro static Drive -Tier 3B Cummins 130HP. Design specifically finished Asphalt , chip sealing maintenance grading, soil compaction. The 516H is compact y....

High Quality, High Performance and Low Lead Time At Austwide Cranes we are a Family-Owned Business who Builds Relationships with our Customers to Provide the Best Products and Services Available on the Market. Our New Overhead Gantry Crane Builds Top the Charts in Quality, Performance and Reliability Guaranteed. Austwide Cranes Offers Over 40 Years Experience in the Industry to Assure we Meet all our Customers Needs. With our In-House Engineering Manufacturing Team All our Products are Engineered and Manufactured to Australian Standards We Can Engineer, Manufacture, Supply and Instal....

The XCMG XDA45 articulated dump truck is specially designed for mining operations, with lowered fuel consumption and increased work efficiency. FINANCE AVAILABLE Loading Capacity - 41 t Gross Weight of Truck - 75 t Max. ....

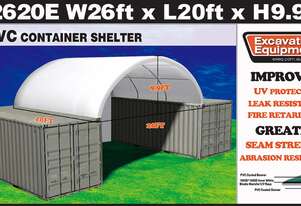

Model C2620E With End Wall Dimensions 26ft W x 20ft L x 9.9ft H from top of container OR 8m W x 6m L x 3m H from top of container High Strength Easily Assembled Inside or Outside Mounted Suited to Australian Weather Cond....

8ton , 3 stage boom , hydraulic running rope , manual drive chaimberlain tractor , all weather cabin , air brakes all round , disc brakes on front , good clean condition tractor crane , ex major manufacturing company , b....

Unused Compaction Wheel to Suit 10-17T Excavator Pin Diameter 65mm Centre to Centre 385mm Between the ears 260mm Shipping Dimensions 1100mm L x 750mm W x 450mm H Weight 450Kgs.....

SUNWARD SWE25UF EXCAVATOR 210 operating hours-Serviced by CEG Hexham 46,000 ono COMES WITH QUICK HITCH AND BUCKET. 3 buckets as in photos. AFFORDABLE PRICE but QUALITY features as well. Sunward European design SWE25UF model is an impressive 2.5ton zero swing excavator. Features include dual auxiliary piping for any hydraulic solution. Powered by Japanese Yanmar engine and hydraulics. Yanmar Engine 3TNV80F-SPSU 14.6KW 2400RPM - 20HP 2400RPM. Machine weight 2650kg . Hydraulics KYB . Hydraulic Pilot Type Control System, wrist control with arm rests. CERTIFIED ROPS 4 post canopy. Rubber ....

Unused Ripper Attachment to Suit 28-36T Excavator Pin Diameter 90mm Centre to Centre 513mm Between the ears 400mm Weight 540kg 1390mm H x 730mm L x 600mm W....

PLATFORM HEIGHT 23.77m UP AND OVER 8.83m HORIZONTAL OUTREACH 18.29m STOWED HEIGHT 3.00m WIDTH 2.49m WEIGHT 17010kg WORKING HEIGHT 25.77m Auslift is Australia s leading machinery hire and sales company with over 30 years ....