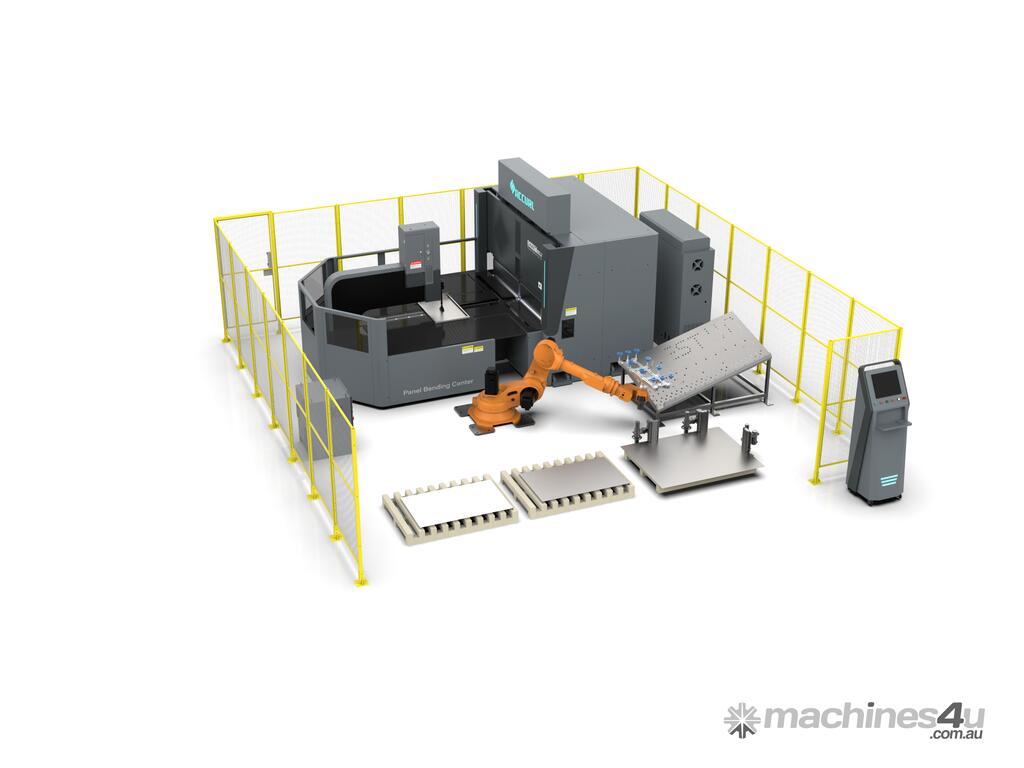

ACCURL PANEL BENDING BEC SMART SERIES WITH LOADING ROBOT:

Servo-electric technology

ACCURL has launched its new BEC SMART panel bender, designed to satisfy the most demanding market needs. With an innovative design, this is the result of more than 35 years of ACCURL’s own know-how in the field of bending

NEW AUTOMATIC PANEL BENDER

BENDING SOLUTIONS:

•ACCURL BEC SMART Smart automatic panel bender has been designed with a modular concept, so that it may incorporate a large range of accessories and offer fully automated solutions.

•The BEC Smart bending cell is a revolutionary bending solution thanks to the “safety integrated” concept that allows the operator to focus only on value-added operations, aided by visual devices and sound signals.

•Its compact layout and combined loading and unloading sequence guarantee high productivity, constituting a very important investment for anyone looking for a flexible and semi-automatic panel bender.

Perfectly equipped for sensitive bending energy efficient solutions:

•Extra blank holder tool

With additional upper blank holders, you can also produce very narrow profiles or components with formed sections near the bending lines. If required, the machine automatically swivels in the ENW extra blank holder from above. The available standard blank holders do not need to be replaced or modified for this.

Connections:

•Compact Solution

•100% Full Servo-Electric System

•Electrical Energy Savings

•Regular Production Independent From the Operator

•Angle drive

With its ingeniously simple continuous path control,

the innovative angle drive of the SMART BEC Center ensures maximum accuracy. The interaction between two axes provides the ideal traverse path to protect the surface of your component. The drive design also makes your SMART BEC Center particularly robust for everyday industrial applications.

The operator has only to load blanks and unload finished components while the BEC panel bender takes care of the rest.

PANEL BENDING BEC SMART SERIES:

The servo motor controls the movement of the positioning L-block, which is fast and accurate

•Maximum comfort for the operator thanks to the lack of physical barriers and work surfaces that can be lowered to facilitate the loading of small or medium-sized parts.

Adapted Automation:

•Modular design allows incorporating additional systems to enable complete automation such as different loading and unloading systems or other ACCURL Sheet Metal equipment.

•The frame adopts a high-precision temperature-controlled furnace, which is tempered, heat-treated, annealed and modulated according to the temperature curve corresponding

to the material, which ensures the lasting stability of the overall accuracy of the machine tool.

UNIVERSAL TOOLING

The Flexible Panel Bender bends the sheet metal with one universal tooling, able to bend various complex shapes.

HORN BLANK HOLDER: (Optional)

Nesting with inner edges can be produced easily with the horn blank holders. The "horns" extend and retract automatically at an angle. This means that the upper blank holder can move downwards without causing a collision between the tool and the bend.

Many sizes available and automation options.