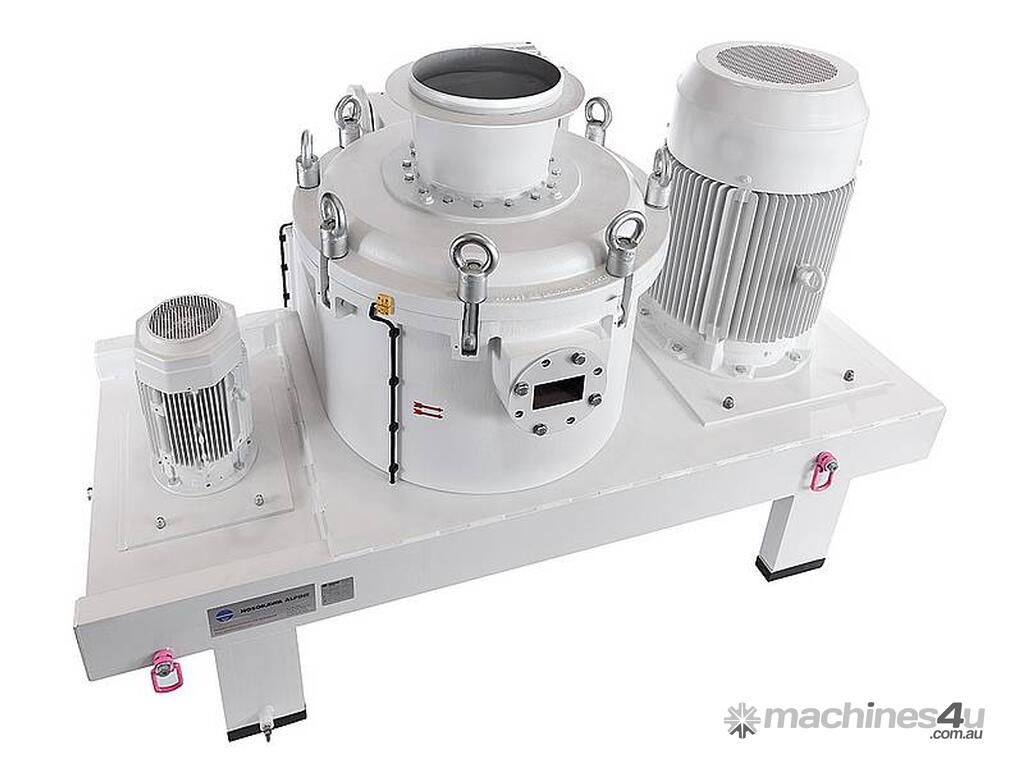

The ACM Classifier Mill is designed for precision grinding and classifying in a single machine, utilizing pneumatic feeding and advanced impact grinding technology. With capabilities to achieve fineness levels of d 97 = 10 µm, this mill operates efficiently at impact edge speeds of up to 140 m/s, ensuring optimal performance.

Key Features

Integrated Grinding and Classifying: Combines two processes for enhanced efficiency.

Compact Design: Space-saving with a high processing capacity.

Gentle Grinding: Maintains product integrity through cool grinding techniques.

Precise Particle Size Distribution: Produces steep distribution curves for consistent quality.

Adjustable Separation Limit: Easily customize separation parameters to meet specific needs.

User-Friendly Maintenance: Simplified cleaning and upkeep processes.

High Availability: Reliable operation with low noise emissions.

Energy Efficient: Low specific energy requirement reduces operational costs.

Pressure Shock Resistance: Safe operation up to PSR 11.

Wear Protection: Designed to withstand abrasion and extend lifespan.

Mill Drying Capability: Suitable for processing materials that require drying.

Variants

The ACM offers four distinct versions and a laboratory model to cater to diverse customer requirements:

ACM CX: Coaxial arrangement for vertical product discharge, preventing caking.

ACM CL: Direct classifier drive for horizontal outlets, minimizing connection length to downstream components.

ACM EC (Easy Clean): Focuses on minimal cleaning time, ideal for frequent product changes.

ACM EC-CL: Combines the compact layout of the CL model with the easy-clean features of the EC model.

ACM 2 and 5: Laboratory and small batch production options with user-friendly Easy-Clean design, requiring minimal space and utility connections.

Applications

The ACM Classifier Mill is suitable for a variety of industries, including:

Chemicals: Bisphenol, tartaric acid, E-PVC, fungicides, herbicides, stearates.

Powder Coating: Epoxy, polyester, hybrids, UV-curing acrylates, polyamide.

Food: Sugar, cocoa, starch, fish meal, xanthan gum, guar gum, lactose.

Pharmaceuticals / Cosmetics: Face powder, ascorbic acid, tartaric acid.

Minerals: Talc, kaolin, calcium sulfate, bauxite, limestone.

This versatile mill is engineered to meet the unique demands of various applications while providing superior grinding and classifying performance.

Ready to take the next step? Contact Klausen Process Machinery today! Let’s transform your challenges into seamless solutions. Your success starts here!