Accurl sheet metal machinery offer high level technology machinery within its market segment and is a progressive forward thinking company constantly improving their products and product range. Its because of this Complete Machine Tools has taken on the agency for Accurl machines in Australia. Why limit yourself to a company that only can supply a laser cutting machine, go with a company who can grow with your business and offer a complete solution for all your sheet metal and fabrication machinery needs under the 1 roof.

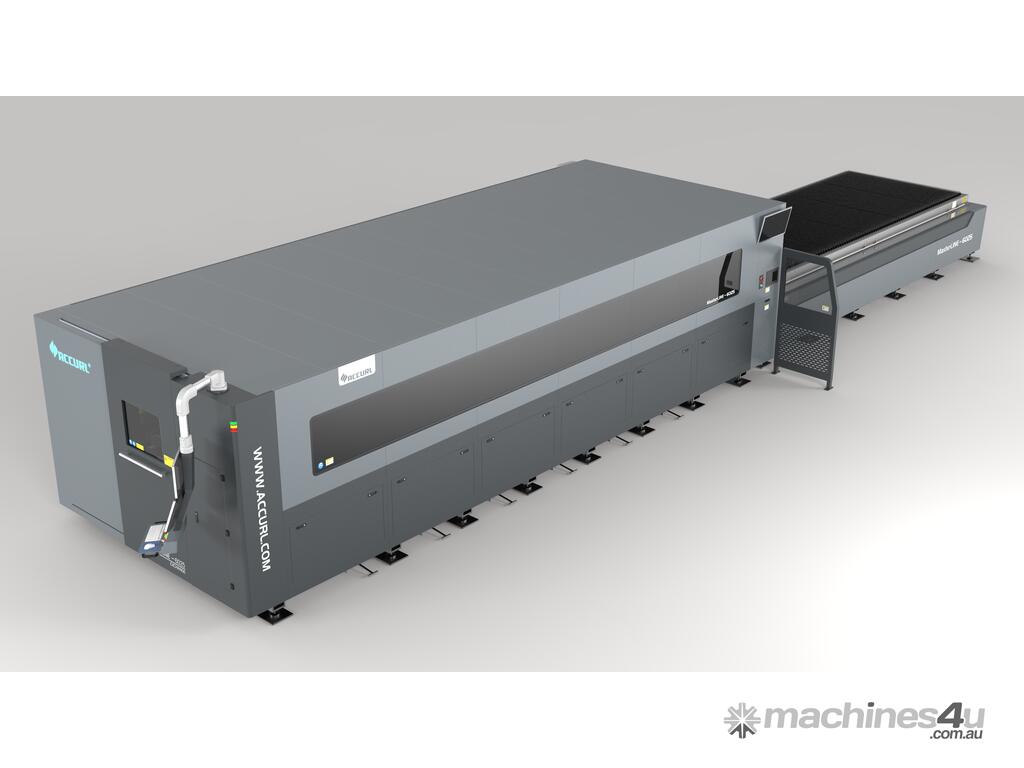

The Masterline series is a very well optioned up machine with a change table. This machine is ideal for a company wanting a work horse and the ability to upgrade many features and add automation as needed. The Masterline Series is fitted as standard with a Boci cutting head, Hypcut twincat dual screen controller, nozzle cleaner and pneumatic safety door at the rear of the machine.

The Masterline comes as standard with an aluminium gantry for the cutting head which drastically reduces the weight compared to a steel gantry. Utilising the aluminium gantry allows the rapid movement to be faster and the control while cutting more stable.

STANDARD FEATURES & COMPONENTS-

-TWINCUT®21" S80 CNC Multi-Touch TwinCAT Control System

-YASKAWA® Highly dynamic EtherCAT servo drive

-BOCI® BLT 4 Series Laser Cutting head (Auto Focus)

-Precision Reducer & RACK System with 3 Arc-min from ALPHA engineering

-ACCURL® Dynamic System 4.0: 2G Acceleration

-ACCURL® Fast piercing 2.0: Ultrafast perforation

-ACCURL® DYNAMIC Shuttle Table 3000×1500mm(Up & Down with Servo Motors)

-Graphite Frame Anti-burn Technology

- Alpha Wittenstein planetary gear head

- Alpha Wittenstein racks

- Rexroth linear guide ways

- Cypcut offline software

-Automatic nozzle cleaning 1.0

-MAX SINGLE-MODULE CW FIBER LASER

-CE Norms: Protective Measures with Real-time monitoring camera

-Class IV safety system and CE marking

-Full automatic voltage regulator System

-HYPCUT®Embedded PCs: Industrial PCs with integrated I/O level

Industrie 4.0 for sheet metal working with TwinCAT Analytics and TwinCAT IoT

-Aluminium cutting head gantry

-Red laser dot sheet alignment system

-Fly cut | frog jump | pre-pierce functions

-Sheet corner auto detection function

-Pneumatic safety door at rear of the machine

-Auto focus cutting head

-Light barrier protection at rear of the machine

-Fully enclosed design

-Laser grade safety glass

-Internal LED lighting

-External 3 colour status lamp

-Solid heavy duty frame for greater vibration absorption

-Pneumatic locking table pics to eliminate any table movement while cutting, this is also fitted with a sensor that if the pins are not in position the cutting will not start.

-Oxygen & Air auto gas selection via a servo valve

-Nitrogen manual selection (Optional auto selection servo valve available)

-Pneumatic suction table zone selection, when cutting in a certain zone on the cutting table a flap controller pneumatically will open allowing all air suction to be concentrated on that zone for better fume extraction to the filtration system.

-Heavy duty box section exchange tables

-Clever door design allowing easy access into the machine for maintenance

CAPACITIES -

- Power source ) 15KW

Options available -

- IPG power source (USA)

- Beckhoff TwinCat touch screen control system (Germany)

- Accurl dust extraction system

- Precitec Thunder cutting head (Germany)

- Precitec ProCutter cutting head (Germany)

- Accurl 3D bevel cutting head (+/- 45 degrees)

- Auto loading / unloading systems

- Smart-Tower systems with 8 - 10 layers available

- Accurl Auto nozzle centering cutting head

- Accurl auto nozzle centering & changer

- iCut (Metalix) offline software

***** A machine size that is larger than a 1.5m x 3m table requires special equipment (flat rack) when shipped from the supplier and the price varies drastically depending the time of the year and how busy the shipping lines are. The above indication of price DOES NOT include any shipping costs *****

NB - Some pictures display optional extras, for a clear indication on what is included and for accurate pricing please contact us for an official quote. (Bevel head is an option) If price is listed as "PRICED FROM" this is purely a broad indication of price.