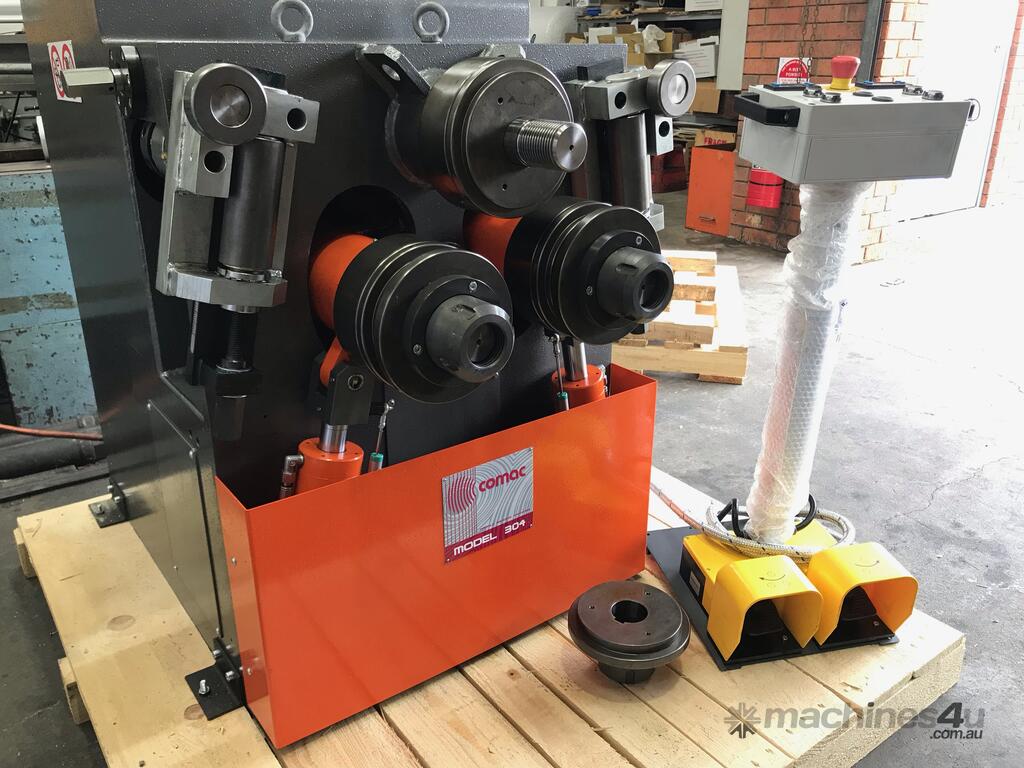

• 3 driving rolls to guarantee maximum drive on the profile

• Bending rolls independently adjustable, for double pre-bending capability

• Fully adjustable lateral guide rolls

• Machine supplied with universal rolls for Flat, angle and solid bars

• Digital read out for position of bending rolls

• Free-standing remote-control pedestal

• Possibility to operate machine both in vertical and horizontal position

• One-piece fabricated steel frame

• Torque limiter installed on top roll shaft

• Shaft and pinions installed on high dynamic load roller bearings

• Gears coupled on splined shafts

Section modulus [cm³] 10

Diameter of shafts (Upper/Lower) [mm] 60

Diameter of rolls [mm] 205

Power output [kW] 3,5

Rolling speed [m/min] 5,2

Weight [kg] 1090

Standard machines are controlled by means of a push button board that allows the variation of the position of the bending rolls and by a pedal that control the advance and retreat of the profile.

Depending on the deformation work to be performed, numerous additional controls are available like, for example, the hydraulic regulation of the lateral guide rolls, the speed regulation by means of a potentiometer, the double speed positioning of the bending rolls and the remote control of the special tooling.

In case a high repeatability is required or if particular bending geometries must be achieved, the machines are equipped with programmable positioner (NC), numerical controls with independent axes and numerical controls with interpolated axes (CNC).