The most-trusted machine retailer in Australia is proud to present to you an EKO ES3512 35 TON 1200mm FULL-SERVO COMPACT ELECTRIC PRESS BRAKE.

EKO full-servo press brakes are manufactured to the strictest-quality standards. The Q345E steel frames are annealed to 1200 degrees before undergoing precision machining and a careful assembly process by experienced professionals.

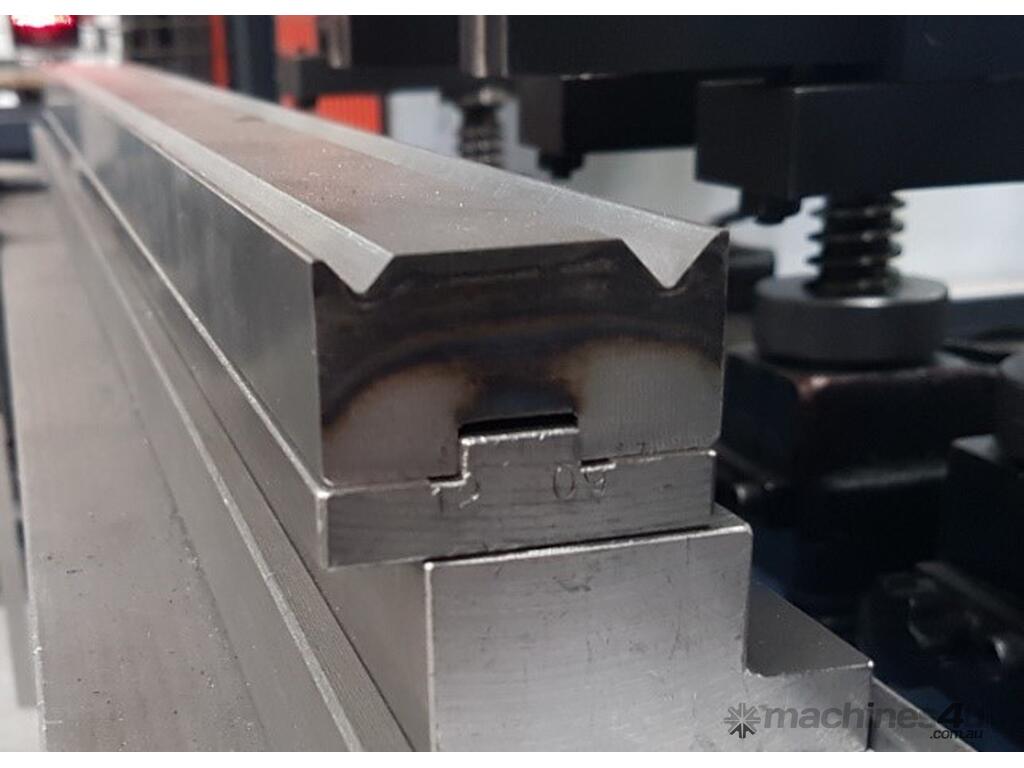

EKO press brakes work on the dual-servo principle with the Y1 (left ram) and Y2 (right ram) axes controlled by powerful SANYO servo motors. This design allows for the highest speed and precision available, and ensures very low running costs. EKO press brakes come equipped with rapid front-loading quick clamps that save time on tool changes and improve efficiency.

Due to their high speed and precision, they are widely used in robot-bending cells.

EKO partner with high-end robot manufacturers such as KAWASAKI, KUKA and YASKAWA to ensure their machines are perfectly suited for high-speed robot-bending applications.

The EKO press brake machines come standard with "NC max" CNC control, similar to AMADA NC9 control. STEP (Germany) and DELEM (Netherlands) graphical controls are also available and are our preferred option for the Australian customer. The highly recommended DELEM DA66T control comes with Profile-T offline software and a large touch screen with clear graphics for easy CNC programming and fool-proof operation.

By building on Japanese and European-style servo machines, EKO have proven their superiority by dominating over 70% of the Chinese domestic market for high-speed electric-servo press brakes.

Full-servo press brakes not only have much higher production rates but are also very economical when it comes to power usage.

----------------------------------------------------------------------------------------------------------------------------------

PRODUCT INFORMATION:

- Model: ES3512

- Capacity: 350KN

- Bending length: 1200mm

- Stroke: 150mm

- Approach speed: 180mm/s

- Open height: 420

- Bend speed: 0.2-50mm/s

- Return speed: 180mm/s

- Power requirement: 15KVA

- Mass of machine (Tons): 3.5

- Back-gauge stroke: 500mm

- Installation width: 1630

- Depth: 1360

- Overall height: 2400

- Installation width: 1340

- Frame gap: 255

- Open height: 410

- Distance between lower and upper table: 290

- Upper table height: 940

- Distance between frame: 1200

- Overall height: 2550

- Controller height: 1000

If you require additional product information, please download the attached PDF.

----------------------------------------------------------------------------------------------------------------------------------

Here at Intermach, we offer:

- FREE DEMOS of the machines we have in our showroom.

- FREE EXPERT CONSULTATIONS to help you select a machine that suits your operational and financial requirements.

- FREE INSTALLATION AND TRAINING upon purchase.

- CONSISTENT AND COMPETITIVE PRICING for our machines based on their capacity.

- AND A LOCAL SUPPORT TEAM OF HIGHLY EXPERIENCED ENGINEERS who are on call for swift repair of any issues that might arise with a machine.

As part of our mission statement, Intermach prioritises customer satisfaction. To that end, we have a growing wealth of references nation-wide who can attest to the high quality of our machines and service.

Phone our sales team now to book a demonstration or a consultation. We look forward to hearing from you!

----------------------------------------------------------------------------------------------------------------------------------

COMPANY BACKGROUND

Intermach is a family-owned company with over 40 years of experience in the industry. We supply both new and used machinery to a multitude of industries—including engineering, fabrication, plastics, recycling, and material handling.

We also sell a versatile range of quality brands to the discerning Australian customer. As the industry’s leading provider, we specialise in sheet metal cutting equipment, fiber laser cutting machines and press brakes.

Our mission is to supply high-quality solutions for all your machinery needs with a focus on versatility, reliability, and service excellence. Customer satisfaction is our top priority.