Everising is synonymous in Australia and world wide for being reliable, great value for money, feature packed and the leader in its market segment.

For over 20 years Complete Machine Tools have been the proud Aussie agents for Everising band saws and circular saws and have forged a very large loyal customer base with numerous customer having multiple Everising machines and 1 customer boasting over 100 Everising saws operating Australia wide.

Everising sits within the top 3 globally in bandsaw production which is an impressive feat. Complete Machine Tools keeps alot of spares parts because of the sheer amount of machines that have been sold in the Aussie market over the last 20+ years so when your saw has an the odd hiccup you can feel confident that Complete Machine Tools will have the part.

Having a great deal of knowledge in sawing and its applications Complete Machine Tools and Everising are the perfect choice when looking for a new band saw whether its a fully auto or semi auto band saw.

A large product range is available that can suit the most demanding of applications regardless of size or complexity.

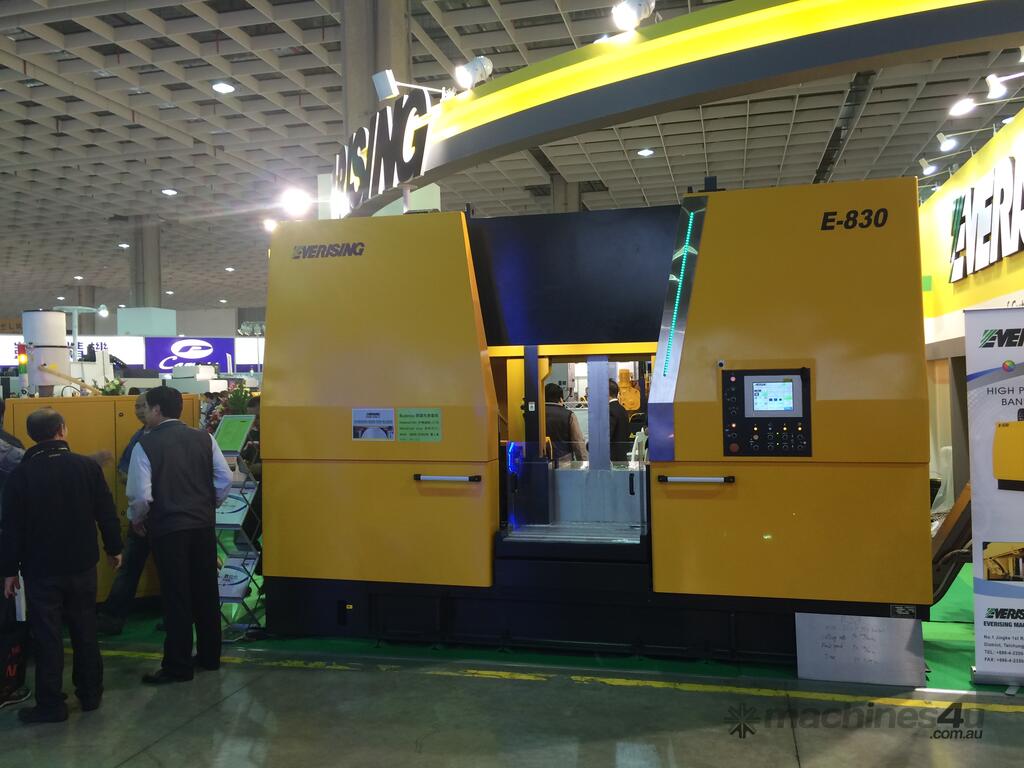

The Everising E-830 auto bandsaw uses a servo hydraulic system and heavy duty linear guideways to control the decent of the frame offering superior control because of the technology and hardware used. The in feed shuttle also uses a the same servo valves for fast positioning with the table sitting on heavy duty linear guideways.

Packed with features and advantages for the owner and the operator the 'E' Series machines are your best value for money investment in a CNC band saw. The E-830 can cut up to 830mm diameter steel.

Technological advances include:

Temperature Cool Down

Using a patented automatic centering compact cooling supply unit coolant is supplied to the cutting area resulting in a 60% cooler cutting temperature. Blade life is dramatically extended and material quality is improved.

Everising Tungsten Carbide Saw Blade

Exclusive to Everising the new generation TC saw blades offer superior cutting performance and enhanced life over other types of blade.

Noise Reduction

Automatic tracking blade guide reduces stress on the blade while the special anti vibration feature provides smoother improved cutting performance with reduced noise.

Testing by Everising engineers has recognised a 13% reduction in the noise from the new 'E' Series machines over previous models.

Reducing noise is a priority of Everising machines as to make the work environment less noisy is to improve the working conditions and amenity of operators thereby allowing improved productivity.

Vibration Suppression

Intelligent MMI for the optimum cutting conditions

Vibration free proportional valves and built in Linear Magnetic switch are employed for accurate bar in feeds.

High integrity linear guide ways are used instead of vertical bars providing vastly improved rigidity.

Automatic blade tracking is actuated by linear guide ways improving performance and reducing vibration in this area.

Precision manufactured heavy duty high torque gearbox powers the saw blade with reduced noise and vibration.

Blade Changing Device

A patented Everising blade changing device improves the task of changing the blade while offering vastly improved protection to the technician. Only Everising has this technology.

Automatic Dual Wire Brushes

The 'E' Series has an exclusive patented dual wire blade cleaning brushes which efficiently clean the chips from the blade providing improved life to the blade and reducing chip jamming during cutting.

The saw blade is shorter which reduces its cost while increasing its efficiency.

An out of square detector further protects the blade without intervention from the operator.

Shockless Hydraulic Bar Feed

Two linear guides are employed for precision and stable last cut holding.

Two sawing positions for long or short material.

In feeding bars are firmly clamped by the twin floating vice at the front and rear.

The saw blade rises up automatically when a sawing cycle is completed.

Everising CNC System

One of the world's largest band saw manufacturers Everising has developed special CNC controls and operator interface which is the very best for the sawing machine application.

Full colour touch screen

Variable settings on screen to optimise the down feeding and cutting method for standard or any special material to be cut.

CNC parameters and data library are available to be adjusted quickly for easy operation and optimum performance.

Machine Status LED

Easy to see the machine status LED is displayed over the full height of the machine making it very easy for the operator to be aware of the machines conditions.

LED is green when cutting is in progress, Blue if the machine stops or a warning is present and Red if a malfunction has occurred.

The controller is Industry 4.0 ready and can be connected to the Everising cloud, this then allows the company the ability to see all cutting data from any device (PC, Ipad, Iphone) so important business decisions can be made with real time cutting data.

If night shifts are run then the management team also has the ability to control and have insights in the going ons.

Standard Features

Variable blade speed controlled by inverter.

Guide arm travels on linear guide way and moves in co-ordination with the moveable vice jaw.

Technical parameters are CNC controlled for optimal processing of the work piece.

Out of square detector.

Hydraulic blade tensioning

Idler wheel motion detector with blade stalling and blade breakage shut off.

Hydraulically actuated carbide blade guides.

Roller work table

Optional Equipment

Profile shape cutting

Automatic loading system

2M long dead roller table - heavy duty

2M long power roller table - hydraulic type