Busch 5.5KW liquid ring vacuum pump system with tank and controller. Part of the water hydraulics system on the tyre curing presses at the now defunct bridgestone tyre plant. The vacuum vessel was built by Forbes pressur....

ENDLESS POWER FOR ENDLESS POSSIBILITIES The 3707-3907 industrial vacuum range is designed and manufactured for the strength, power, and reliability required for continuous and heavy-duty conditions. The oversized filter ....

Its time to turn over our SCM Group Technology Centre Demo machines First in Best Dressed. Price does not include delivery or installation The new generation of Nesting CNC machining centres meets the needs of a market increasingly oriented towards flexible and batch-1 production, combining excellent performance, maximum configurability with increased flexibility and productivity. Every detail is designed to make any performance accessible, leading to efficiency, quality and business evolution. Advantages. Every detail is designed to make any performance accessible, leading to effic....

HAFCO-WOODMASTER BP-480 CE Wood Band Saw 2 Blade Speeds - 488 1010m min Includes Magnetic Safety Brake System - 415V 465mm Throat Depth x 310mm Height Capacity CALL NOW AND DO A DEAL ADD THIS ASSET TO YOUR WORKSHOP WE OF....

The 5-axis machining center for furniture manufacturers Project 475 is the 5-axis machining center for advanced furniture manufacturers. The cantilever structure allows loading of rather wide panels. The use of birotativ....

This vacuum lift is in great condition. From a reliable brand of German origin, it has a working load limit of 45kg. System is made of modular parts, making it easier to repair and or replace. With the simple one-finger ....

Test VR now testing 1990 - 2022....

Saving you time is our motivation Time, the most important resource in a modern workshop was one of the main focuses whilst developing the new tempora machine concept. Processing edges needs to be as quick, easy and effi....

ProfiStop Alpha is a simple to use auto measuring stop for high-accuracy medium-heavy materials cutting. Speed up your cutting through the roof, simply, and introduce advanced job-management functions to run your product....

This machine is a quality Italian build, manufactured by CASOLIN Italy. The MEGA 23 4 an ideal machine which would fit in well to a joinery shop or jobbing machine for larger manufacturers MADE IN ITALY, Quality Four sid....

Anderson Genesis Plus Series Built for the Work Ahead When it s time to move faster, cut smarter, and scale your business step into the Anderson Genesis Plus Series. This is not just another nesting CNC. It s your next competitive edge. Engineered from the ground up to handle real-world production pressure, the Genesis Plus brings the muscle, speed, and reliability serious shops demand. Whether you re running kitchens all day or pumping out commercial joinery, this machine won t flinch. Built to Perform. Ready to Run. Choose your perfect fit Genesis Plus 49 2700 x 1300 mm Genesis Plu....

Wood shavings extraction system and burner, comes with hot water heat exchanger for heating of factory location via heat panels. also come with a floveyor, and all duct systems as shown in pictures and video. Can sell as....

HAFCO-WOODMASTER ST-254PT Table Saw Package Deal 560 x 800mm Cast Iron Table 254mm Saw Blade Includes 1500mm Sliding Table CALL NOW AND DO A DEAL ADD THIS ASSET TO YOUR WORKSHOP WE OFFER MACHINERY SOLUTIONS AT AFFORDABLE....

Proudly made in Italy the SCM TF130 Spindle Moulder is the best solution for every application. In either a very professional manual version or with Electric movements. Technological devices in the electronic version tha....

MultiCAM SR-3618v Compuerised CNC Routing Machine with A2MC controller complete with dust extraction unit CNC Router was purchased for 120,000 GST back in 2010 Dust extraction unit was purchased for 14,896 GST in 2013 both units have had minimal use and can be inspected at factory in Notting Victoria by appointment....

Enhance your woodworking capabilities with the Biesse Akron 435 Edgebander, a reliable machine crafted to deliver precision and efficiency. Built in 2013 and maintained in good condition, this edgebander is ideal for applying edgebanding to various types of panels with ease and accuracy. The Biesse Akron 435 features advanced technology that ensures consistent results, making it suitable for both small-scale workshops and larger production facilities. Its ergonomic design facilitates ease of operation, while robust construction ensures durability and reliability over years of use. Wh....

E-COAT Basic series equipment is suitable for manual applications. E-COAT Basic does rapid coating on tough surfaces with high coating performance. The unit has 3 default presets namely straight surface coating, secondar....

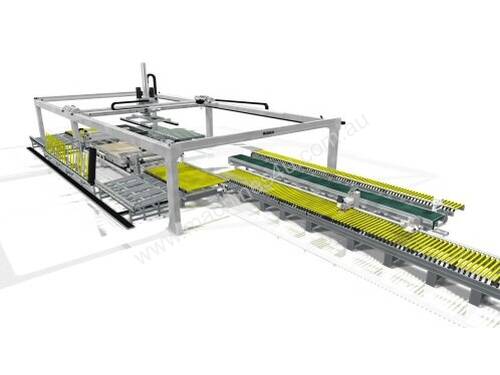

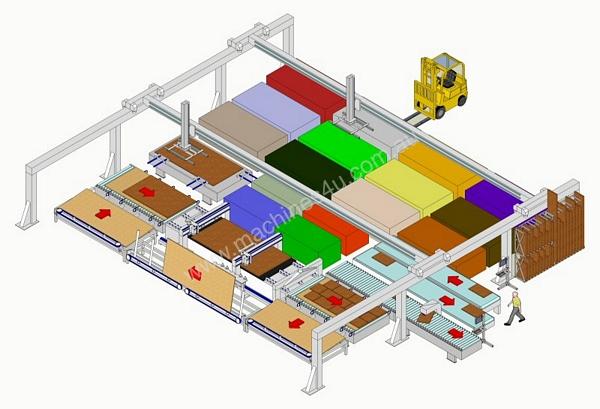

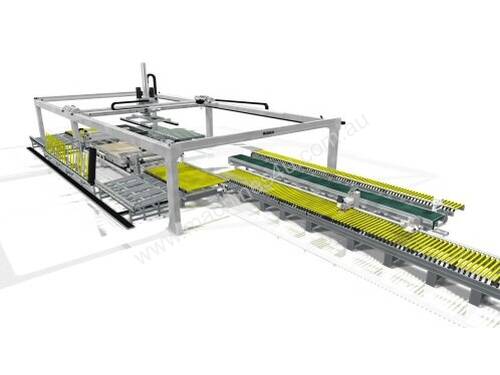

THE SOLUTION THAT COMBINES QUALITY AND TECHNOLOGY Modular machining centres designed and developed to satisfy the requirements of furniture manufacturers. Performance without comparison with the mobile gantry structure a....