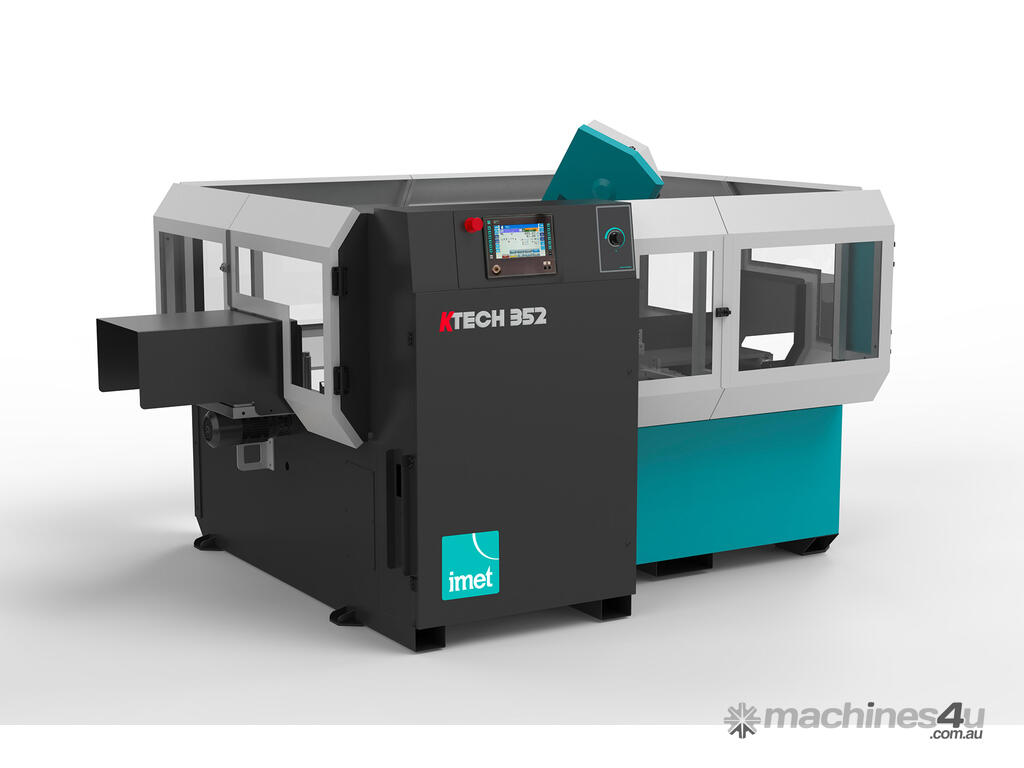

The Imet KTECH 352 F1200 is a pivoting bandsaw with automatic NC rotation and integrated 1200mm motorized feeder

intended to be used for structural steels and steel works factories. The machine is equipped with an easy and

intuitive HMI by 10" touch screen display and can provide a cutting range from +60° to - 45°. Full compatibility with

Industry 4.0 system. The IMET range is manufactured in Italy.

10" touch screen display

KTECH 652 has an easy and intuitive interface dedicate to optimize the user-experience: thanks the CNC system and 10" touch screen display the user can manage all the machine operative function, set up 99 cutting program and multiple cutting length on the same bar, set the number of feeder stroke, the number of pieces and blade speed. It's also possible to do an auto diagnostic to detect errors.

NC control

KTECH line automatic bandsaws have an innovative 4 controlled axis system

(laterial movement and closing of the vice, material feeding and sawframe

rotation), all managed by numeric control. All the machine movement and setting

can be controlled and modified via touch screen display.

Sawframe

The bow is made with electrowelded steel and has tubolar section, big diameter

pulleys (380mm) with hinged blade-cover carter. The sawframe also has an easy

blade-changing system provided by support piston. Hard metal pads on mobile

blade-guides optimize the blade alignment.

Blade and endcutting

KTECH 352 uses a 27x0.9mm blades with high working tension (up to 1900kg/cm2)

that gives high results in terms of material feeding and cutting, allowing to reduce

vibrations and strain on the band and avoid breakages that could damage the

cutting quality. As all Imet machine, also this model ends the cut with the blade

not in parallel with the plate: this systems allows to cut always only a section of

the material even when working with squares.

Sawframe movement

Sawframe rotation and angle setting position is managed by motoreducer

controlled by inverter and it's provided by rack and pinon. The rotation is blocked

by an hydraulic cylinder once the set angles is correct. The machine automtically

synchronized the bow rotation with the vice closing and movement. Descent is

hydraulic with pressure regulators on the mobile panel control, next to the HDI

system.

Mechanical detection device

Mechanical material detection system automatically detech the first point point,

allowing the fast approach of the bow to the material. The end-cutting process is

managed by a microswitch placed on the mobile blade guides that automatically

detect when the cutting process ends.

F1200 integrated feeder

Once loaded, the material movement is provided by the integrated motorized

feeder equipped with self-braking electric motor, incremental screw (that also

optimizes to have perfect positioning and accuracy), inverter and encoder. The

feeder slides on chromed bars with a floating plate to ease the loading of material

that is not perfectly straight.

Cutting precision

KTECH line bandsaws have an automatic control of the pieces size thanks to the

infinitesimal encoder and the automatic correction of the cutting lengths. Thanks

to the innovative angle measurement system (angle reading is set outside the

machine center), the machine has an high positioning accuracy and the best

cutting precision.

Industry 4.0 Ready - SAWfactory + RealTime OPTIONAL

IMET automatic machines can be connected to the company network and be used

remotely thanks SAWFACTORY and modem. SAWFACTORY is a dedicated software

which allows to manage the cutting process from the office desk by setting cutting

programs and monitoring the workflow thanks to the dedicated web app. The

software also allows to also receive assistance by our technicians remotely.

Discover SAWFACTORY: bit.ly/2RuxHuX

Industry 4.0 - RealTime Kit for OPTIONAL

The kit allows to send from the machine to the MES information in real

time about: machine status, cut pieces situation, automatic cycle progession. The

connection is provided via a Web service made available by the user on his own

LAN; the webservice will act as a filter between the bandsaw and the internal MES

(the kit is available only if the "Industry 4.0 Ready" package is already installed

Industry 4.0 Ready - OneLoad Kit for MES OPTIONAL

The kit allows to load from the company office/MES to the machine software a

cutting list/program to optimize the internal workflow while avoiding possible

mistakes made by the machine operator. It's necessary, for the customer, to have

an FTP server on te same LAN where both SAWprogram software and cutting

program are installed. A "shortcut" is enabled on the machine control to load the

cutting lists and start the cycle (the kit is available only if the "Industry 4.0 Ready"

package is already installed).

Cutting capacity at 0° Round: 305mm - Square: 250mm - Rectangular: 350x200mmm

Cutting capacity at 45° left/right Round: 255mm - Square: 230mm - Rectangular: 230x200mmm

Cutting capacity at 60° left Round: 175mm - Square: 155mm - Rectangular: 170x100mmm

Cutting capacity with bundle device Max 300x160mm - Min 85x10mm

Cutting capacity at 0° - solids (C45) 200mm

Minimum cutting length 20mm

Minimum cutting diameter 20mm

Minimum scrap-end 150mm

Blade size 3370x27x0.9mm

Blade motor 1.8KW

Blade speed range 15-100 m/min

Feeder (single stoke)- motor power 1150mm with ballscrew - 0.75KW

Hydraulic unit tank capacity 20l

Coolant tank 100l

Machine size 2935x2400x1900mm - 2100kg