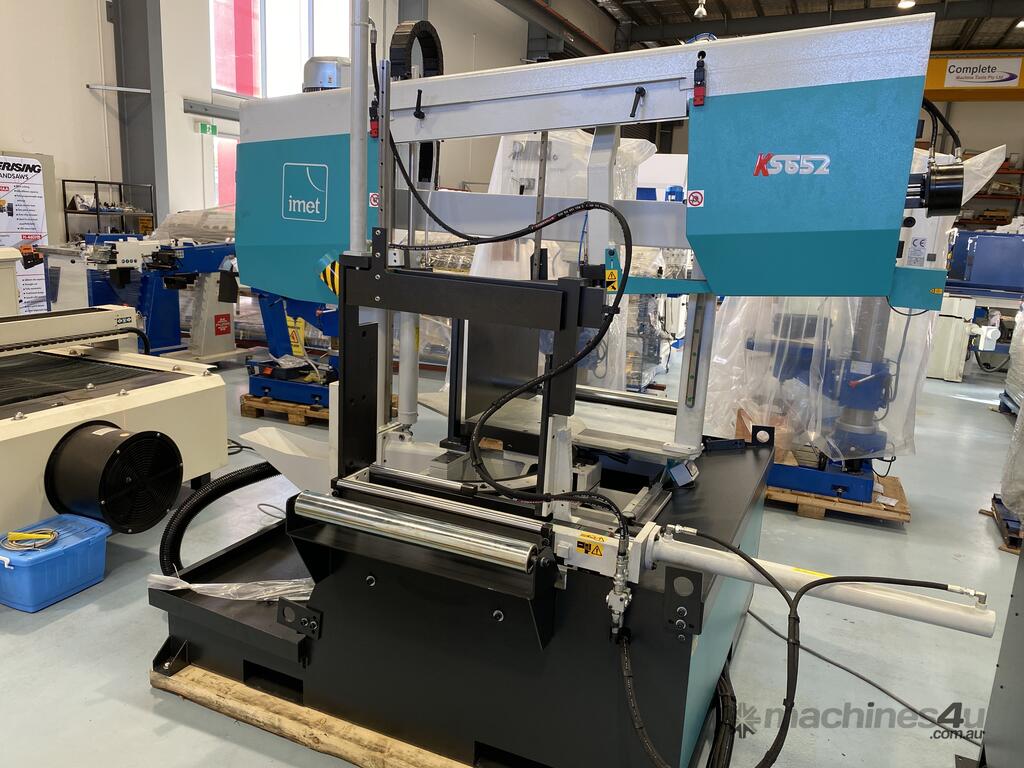

Imet KS 652 is the semi-automatic double column sawing machine for cutting metal structural work, pipes, profiles and beams. The machine can cut right and left up to 60 ° and is equipped with a large support surface and visual reference on a graduated scale distant from the center of the machine for greater precision and ease of reading. The Imet range is quality made in Italy.

Vice

The vice slides transversally on the work surface, linear guides, locking and rapid approach, complete with standard pressure reducer. All the saws of KS series (450, 502, 620 and 652) allow to fix the material clamping vice only once and then to rotate the arc for cutting both right and left (up to 60 °).

Large working table

Easy to use thanks to the rotating work surface integral with the arc and the blade passage to optimize the material support system during processing in all angles.

Cutting precision

The cutting precision is ensured by the graduated scale (on the work surface) which constitutes a visual reference for the operator in case of angle cutting. There're also automatic stops at 45°left, 0 ° and 45 ° right. To increase cutting precision, IMET band saws are equipped of a system for detecting degrees of cut away from the center.

Rigid saw frame

In electro-welded steel, the blade has an inclination of 6° to improve the penetration in the material and optimize the execution of the cut. The rotation of the arc is done by bearing preloaded. The KS 652 blade has has a tensioning of 2000kg / cm2 and is equipped with a control microswitch for immediate stop in case of blade breaking or power failure.

Blade tension

The blade of KS 652 has a tension of 2000 kg / cm2 and is equipped with a control microswitch for stopping immediately the blade in case of breaking or tension failure. The machine is equipped with blade guide sliding on linear guides for easy adjustment with hard metal inserts and additional bearings to improve alignment.

Material detection device

To facilitate the approach of the blade to the material KS450 mounts a device for detection automatic cutting start and end point.

Control panel

KS 652 is equipped with a mobile control console with control LED for tensioning the blade, opening of the blade guard, motor thermal block and electrical tension. Through the control the operator can choose between 3 different ways of cutting end: ascent of the bow with stopped blade, ascent of the bow with blade in movement and end of cycle without bow ascent.

Blade cleaning

Motorized nylon cleaning brush for blade, driven by motor pulley to always keep in perfect condition the cutting blade.

High performance package (Optional)

KS 652 offers the possibility to increase cutting performance through the 4KW gear motor, blade from 41mm high and hydraulic tension.

Minimal lubrication system (Optional)

The lubrication system cancels the dispersion of the coolant without damaging or affecting the life of the blade. The system is equipped with a 1.3l tank and nozzle.

Loading/unloading roller table

Roller conveyor suitable for the unloading and loading side. Length 1.5m, 1 pedestal, max loading 1500kg.

Unloading roller table (optional)

Unloading roller table with digital reading and manual movement. Available : -RTL3KS600 Measuring length of 3m, 3 pedestals, max loading 3000kg; -RTL6KS600 Measuring length of 6m, 5 pedestals, max loading 6000kg.

Motorized loading roller table (Optional)

Loading motorized roller tables, with chain transmission and motor reducer managed by inverter, with mobile keyboard. Available : -3m, loading 3000kg; -6m, loading 6000kg; -9m, loading 9000kg; -12m, loading 12000kg.

Motorized unloading roller table (Optional)

Unloading motorized roller table, with chain transmission and motor reducer managed by inverter, available only together with loading roller table. Available: -3m, loading 3000kg; -6m, loading 6000kg; -9m, loading 9000kg; -12m, loading 12000kg.

Digital reading length stop (Optional)

Digital reading length stop with manual positioning with automatic slowdown sensors, available only together with unloading motorized roller table

Measuring length 3m; Measuring length 6m; Measuring length 9m; Measuring length 12m

Motorized length stop (Optional)

Numerical control motorized measurement RR with fast approaching for automatic slowdown of the piece (to be ordered coupled with automatic conveyors) -RR6S 6m measuring length -RR9S 9m measuring length -RR12S 12m measuring length

-Double miter 60 - 60 degrees

-Hydraulic vice clamping

-Inverter for blade speed

-24V control panel

- Linear guides on frame

- Linear guides on vice

- Linear guides for vice movement

- 650 x 450mm capacity

- Separate movable control panel

- Saw frame down feed knob on control panel

- Blade pressure gauge & safety cut off switch

- Cylinder with valve control for descent on the saw frame

- Hydraulic return on the saw frame

- Rapid approach device for sensing top of material

- Safety switch on removable blade cover (machine must switch off)

- Blade cleaning brush

- Carbide blade guides

- Scale for angle

- Coolant supply direct to blade

- Cut off switch for bottom of stroke of saw head

- 0 degree locating pin

- Coolant system

- Rear support roller

- 415V | 50HZ | 3PH

TECHNICAL INFORMATION

Cutting capacity at 0°

Round: 510mm

Square: 480mm

Rectangular:650x450mm

Cutting capacity at 45° left

Round: 440mm

Square: 430mm

Rectangular:430x430mm

Cutting capacity at 45° right

Round: 440mm

Square: 440mm

Rectangular:440x440mm

Cutting capacity at 60° left

Round: 250mm

Square: 250mm

Rectangular:250x450mm

Cutting capacity at 60° right

Round: 250mm

Square: 250mm

Rectangular:250x450mm

Cutting capacity (BUNDLE) Max: 650x450mm

Min: 125x15mm

Cutting capacity at 0° solids (350mm with 4KW motor reducer and blade 41mm)

Min. scrap-end with bundles 250mm

Blade motor 4 KW

Blade speed 15 - 100 m/min

Blade size 5230x34x1.1mm (option blade 41 mm)

Blade tensioning 2000kg/cm2

Weight 2100kg

Dimensions 1895x2870x2300mm