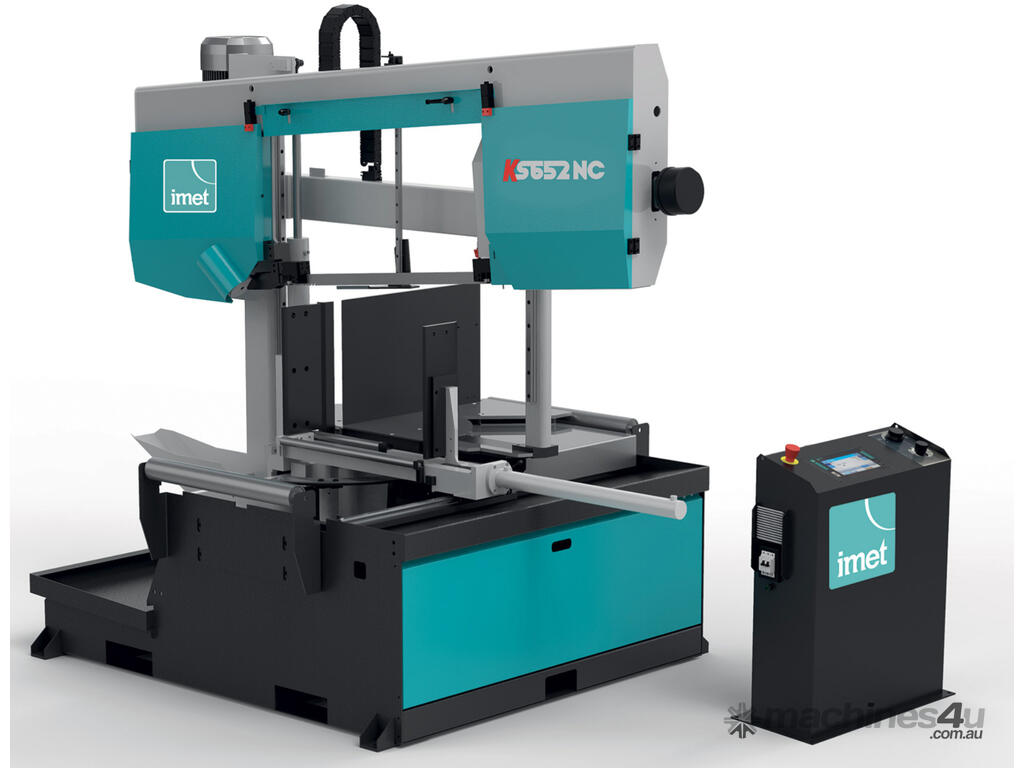

The IMET KS 652 NC is a semiautomatic double bandsaw with NC control on the saw frame rotation and 7" touch screen interface to set the cutting angle. The machine is the perfect working tool for frame producers, steel works factories and

structural steels and is able to cut beams and pipes up to 60° left and right. Bow down feed is processed by hydraulic

cylinder. The Imet range is quality made in Italy.

Hydraulic vice

The fixed vice slides transversely on the work surface with linear guides and is

complete with a pressure reducer as standard. Displacement by hydraulic cylinder,

controlled by encoder and hydraulic brake. The vice is also equipped with an

automatic control system for the size of the piece via encoder.

Wide working area

Ease of use is ensured thanks to the large work surface with rotation integral with

the bow and blade passage to optimize the penetration of the material. The

electro-welded steel structure guarantees absence of vibrations and maximum

support of the material during cutting.

Cutting precision

The cutting precision is ensured by the graduated scale (on the work surface) which constitutes a visual reference for the operator in case of angle cutting. There're also automatic stops at 45°left, 0 ° and 45 ° right. To increase cutting precision, IMET band saws are equipped of a system for detecting degrees of cut away from the centre.

Saw frame

Machine's saw frame is electro welded with rigid structure and big thickness. The

massive structure helps reduce vibrations, binding or slowing during the cutting

process, saving sawblade life and durability. High cutting performances even on

the biggest sections and full materials are provided by the canted blade.

Blade tension

The blade of KS 652 has a tension of 2000 kg / cm2 and is equipped with a control

microswitch for stopping immediately the blade in case of breaking or tension

failure. The machine is equipped with blade guide sliding on linear guides for easy

adjustment with hard metal inserts and additional bearings to improve alignment

Optimized cutting process

The inclined blade allows the work cycle to be optimized: the blade is in fact

never parallel to the surface and is never (not even in the case of a square tube)

working on a solid surface, but always on a section of the material, even during

cutting the final part of the bar. This helps save unnecessary stress on the tape,

safeguarding its lifespan.

Motorized rotation

The automatic saw frame rotation is managed by motor reducer and inverter. An

hydraulic piston lock the bow once it reached the set position. To keep clean and

allows perfect rotation, an air-cleaning system is working during the rotation. Bow

rotation power is 0.55KW.

Saw frame descent

KS 652 NC saw frame descent is hydraulic with easy regulation by two handlers

positioned on the mobile independent console. The machine also mounts a

mechanic detection device to ease the blade approach to the material and detect

the first cut point.

HMI interface

KS 652 NC's an easy and intuitive interface dedicate do optimize the user experience:

thanks the CNC system and 7" touch screen display, the user can

manage all the machine operative function, set up 99 cutting program and

multiple cutting length on the same bar, set the number of feeder stroke, the

number of pieces and blade speed. It's also possible to do an auto diagnostic to

detect errors.

Material detection device

To facilitate the approach of the blade to the material KS450 mounts a device for detection automatic cutting start and end point.

Blade cleaning

Motorized nylon cleaning brush for blade, driven by motor pulley to always keep in perfect condition the cutting blade.

High performance pack (Included)

It's possible to extend the machine cutting performances, like the cutting capacity

at 90° of full solid bars by adding the dedicated pack that includes: 4kw Bonfiglioli

motor, 41mm h. blade and hydraulic tensioning system. The pack also improves

KS 652 NC performances on big size diameters.

Minimal lubrication system (Included)

The lubrication system cancels the dispersion of the coolant without damaging or affecting the life of the blade. The system is equipped with a 1.3l tank and nozzle.

Laser (Included)

It's possible to add as optional a laser ray that points the cutting line on the

material to optimize the user workflow.

Bundle cutting device (Optional)

The bundle cutting device is required when working with bundles of tubes or

profiles. Adding the device will change a little bit the machine cutting capacity:

max. 650x450mm, min. 125x15mm. When the device is mounted, the machine

can only cut at 0°; if the user needs to cut with different angle, the device must be

disassembled

Loading/unloading roller table (Optional)

Roller conveyor suitable for the unloading and loading side. Length 1.5m, 1 pedestal, max loading 1500kg.

Unloading roller table (optional)

Unloading roller table with digital reading and manual movement. Available : -RTL3KS600 Measuring length of 3m, 3 pedestals, max loading 3000kg; -RTL6KS600 Measuring length of 6m, 5 pedestals, max loading 6000kg.

Motorized loading roller table (Optional)

Loading motorized roller tables, with chain transmission and motor reducer managed by inverter, with mobile keyboard. Available : -3m, loading 3000kg; -6m, loading 6000kg; -9m, loading 9000kg; -12m, loading 12000kg.

Motorized unloading roller table (Optional)

Unloading motorized roller table, with chain transmission and motor reducer managed by inverter, available only together with loading roller table. Available: -3m, loading 3000kg; -6m, loading 6000kg; -9m, loading 9000kg; -12m, loading 12000kg.

Digital reading length stop (Optional)

Digital reading length stop with manual positioning with automatic slowdown sensors, available only together with unloading motorized roller table

Measuring length 3m; Measuring length 6m; Measuring length 9m; Measuring length 12m

Motorized length stop (Optional)

Numerical control motorized measurement RR with fast approaching for automatic slowdown of the piece (to be ordered coupled with automatic conveyors) -RR6S 6m measuring length -RR9S 9m measuring length -RR12S 12m measuring length

Cutting capacity at 0° Round: 510mm - Square: 480mm - Rectangular: 650x450mm

Cutting capacity at 45° left Round: 440mm - Square: 430mm - Rectangular: 430x430mm

Cutting capacity at 45° right Round: 440mm - Square: 440mm - Rectangular: 440x440mm

Cutting capacity at 60° left Round: 250mm - Square: 250mm - Rectangular: 250x450mm

Cutting capacity at 60° right Round: 250mm - Square: 250mm - Rectangular: 250x450mm

Cutting capacity with bundle Max: 650x450mm - Min: 125x15mm

Cutting capacity at 0°, solids (C45) 280mm (350mm with High Performance pack)

Minimum scrap-end with bundle 250mm

Blade motor 3KW (4 KW)

Blade speed 15 - 100 m/min

Blade size 5320x34x1.1mm (41mm)

Blade tension 2000kg/cm2

Sawframe rotation 0.55KW

HMI and panel control Touch screen 7" with NC

Size 1895x2870x2300mm - 2100kg