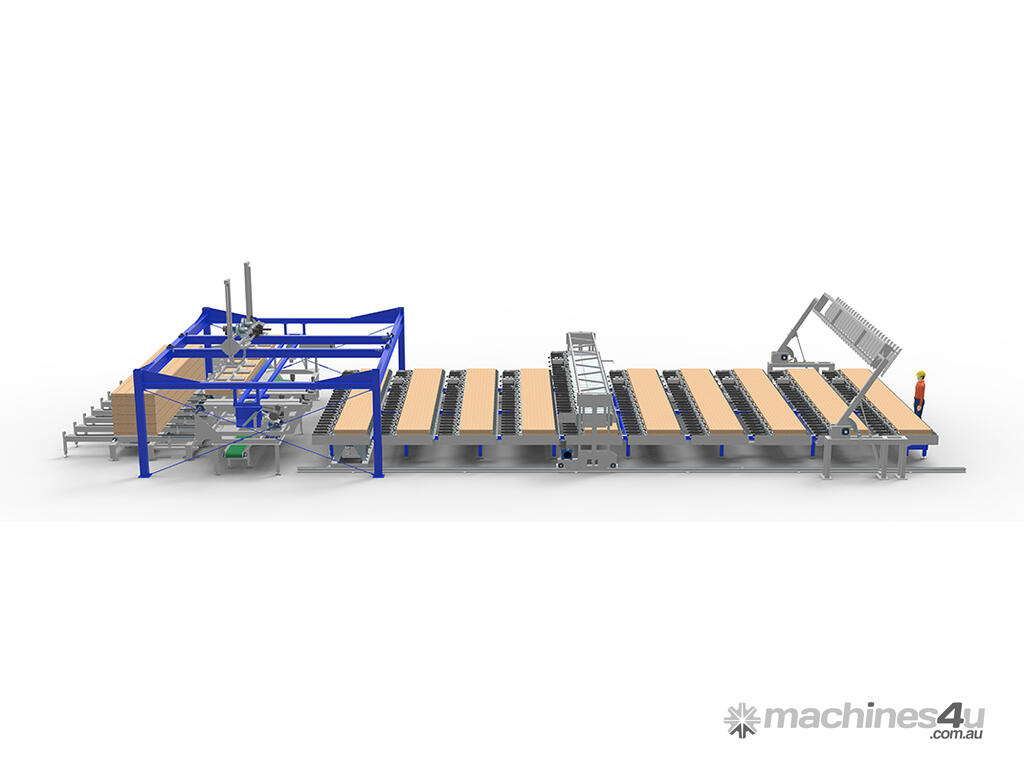

The laminating line is an automated press with trimsaws and timber stacking. The timber is loaded at one end and comes out glued, cut to length and stacked.

The line can be fully integrated into your existing timber management system to streamline barcoding, timber allocation, job costing, efciencies and more. The line is built with heavy duty steel and quality components to ensure it is robust, reliable, and a long lasting machine.

REDUCED LABOUR: Reduces labour from 15+ employees to 4.

HIGH PRODUCTION: Capable of 100m / hr with a 40 sec. cycle time.

LARGE CAPACITY: Up to 7.5m long x 900mm wide x 150mm high pressings.

EVEN PRESSURE: Accurately controlled and even pressure on each glue line.

INTEGRATED CONTROLS: Integration to existing timber management systems.

QUICK JOB CHANGES: Change between jobs on the fly without missing a beat.

MULTIPLE SAWS: Up to 5+ saws with servo control for high accuracy.