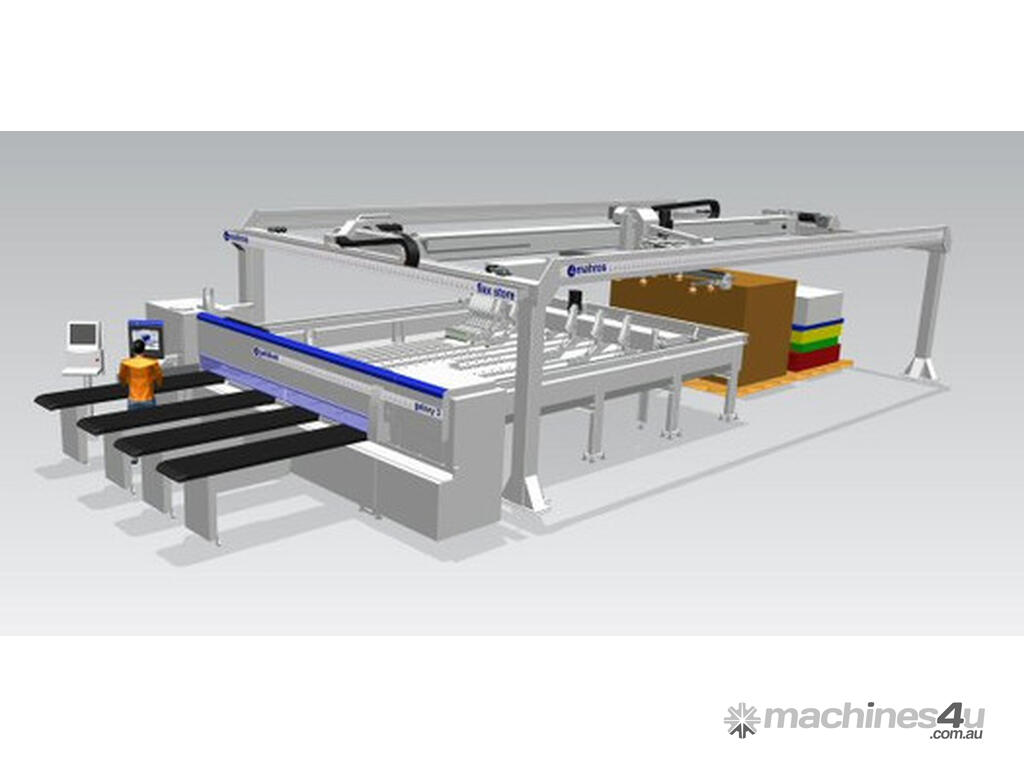

CELL GALAXY 3 + FLEXSTORE EL

Full automatic cell designed to match production requirement as high flexibility and cutting quality for BATCH 1. The Cell includes the new single-blade panel saw machine Galaxy 3 100 and it is equipped with mobile grippers device FLEXCUT and with three axes loading System Flexstore EL.

The cell can be fitted on the rear with a preloading panels area and automatic labelling system for an high versatility of utilization, high cutting quality _single panel and stack of panels_ with a considerable reduction of labour costs and also for:

• High flexibility

• Custom made solution

• Reduced cycle time

• Framework strength and reliable

• Maximum integration of the productive process by SCM GROUP software

• Offcuts management

• Mixed stacks management

Advantages:

1. FLEXSTORE EL: production flexibility

Panels stacks in different sizes and types

2. CUSTOMIZED

Cells are customizable for cutting quantity and warehouse dimensions to match any customer needs

3. WATCH STORE

WATCH STORE, the integrated software with user friendly interface that allows to manage various machining modalities granting high productivity performances.

High performance and Energy saving with Sav€nergy

Technical data:

GALAXY 3 110

Single beam panel saw for industrial applications

• Cutting dimensions: 4500x4300 mm

• Max. blade protrusion: 110 mm

• Max. saw carriage speed: 170 m/min

• Max. pusher speed: 135 m/min

• 7,5 kW-50Hz main blade engine

• Saw carriage run, and operating units and prismatic guides

• HI-TRONIC device

• FLEXCUT 1/S for simultaneous execution of differentiated cuts

FLEXSTORE EL

Loading flexible warehouse with 3-axes (opt. 4-axes)

• Variable configuration of number station – available surface up to 12x60 mt

• Panels thickness: 10 ÷ 60 mm (opt. from 3 mm)

• Panels length: 2.440 ÷ 4.250 mm

• Panels width: 800 ÷ 2.200 mm

• Max. panel weight: 200 Kg

• Loading arm with 3 degrees of freedom + rotation (opt.)

• Vacuum loading arm with electronic adjustment depending of the dimension of the panels

• Device for the automatic detachment of the panels

• Check device for the detachment of the panels

• offcuts management

• Mixed stacks management