The Ercolina 2-speed, three-phase machine offers durable, high-performance bending with the patented non-mandrel system, ensuring precise bends with small radii no internal mandrel needed. Ideal for various applications, it features quick tool changes and a rugged, user-friendly design. Manufactured in Italy, this machine is available exclusively in Australia through Magnum Machinery. Key Features 2-Speed Operation for versatile performance Non-Mandrel Bending for high-quality, tight-radius bends Quick Tool Changes for efficient transitions Heavy-Duty Construction for long-lasting us....

CNC MACHINERY SALES AUSTRALIA PRESENTS - Table sizes 2M x 1.7M up to 6M x 3.1M the Eumach DVM ram type double column vertical machining centres are designed for heavy duty applications where rigidity and accuracy are ess....

3HP variable speed head NT30 R8 spindle taper 3HP powerful motor Square slideways on knee. Extra wide table working area 50 x 10 Hardened and ground X,Y axes and table surface MODEL PK-GRSM-B Table 1270 x 254mm TRAVEL Lo....

Advantages Safe, non-contact, no damage to substrate Environmental protection, no secondary pollution, and removed substances recyclable Precision and controllable, optional area cleaning, and micron level precision control in thickness direction Ultra high cost performance, laser cleaning equipment in the use of no consumables, only power consumption 200W series laser cleaning machine can be used to remove rust, paint, oil and oxide film on all metal and some non-metal surfaces, as well as the cleaning of black ash, carbon deposition and oil stain on the surface of parts after weldi....

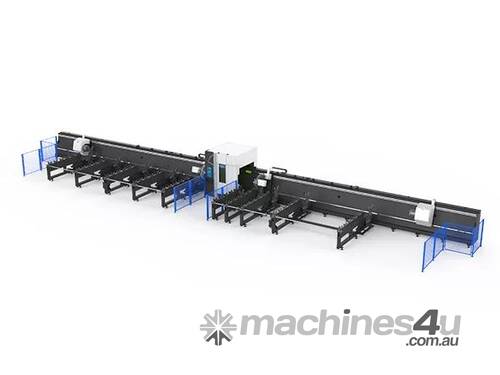

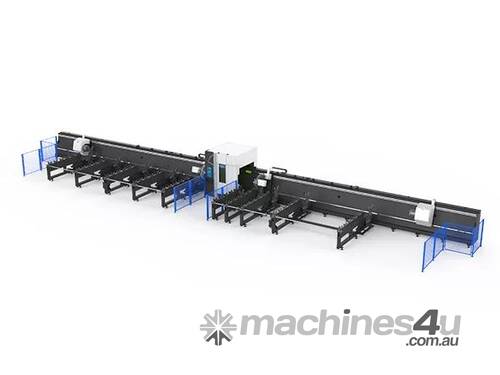

The Accurl tube lasers are a step ahead of their competitors being a machine that s been produced and constantly improved upon by Accurl for a number of year, Accurl sheet metal machinery offer high level technology mach....

The GF Smart is ONE all-inclusive package to start cutting now Farley LaserLab s GF Smart Pro, Inclusions - 1.5m x 3.0m plate Cutting Area enclosure transfer table - 12kW Raycus Fiber Laser Source - CYPCUT BLT Auto Focus Cutting Head - Hand held controller - Digital servo system - Helical rack and pinion drives and Linear Rails - 3 gases, Oxygen, Nitrogen or Air proportional control valves. - CYPCUT CNC Controller - CYPNEST Auto Nesting Software - 3 zone downdraft dry table - Roll out collection trays - Water Chiller Unit - Automatic lube system for pinions bearings - Farley Installa....

China s largest and most trusted fiber laser producer is finally available in Australia with local support Fiber welding is the next big step in factory efficiency, it s fast easy to use and offers an incredible finish. ....

BODOR BODOR CT CE 3kW Combo Sheet Tube Laser Cutting 3048 x 1524mm Table 6m Max Tube length For cutting pipes and sheet metal CALL NOW AND DO A DEAL ADD THIS ASSET TO YOUR WORKSHOP WE OFFER MACHINERY SOLUTIONS AT AFFORDA....

Compact bed type milling machine POINT Based on KMB series, POINT series with HEIDENHAIN TNC124 are fully adequate for straight cut control for milling, drilling and tapping supported by a floating tap holder and even circular path with circle hole pattern up to 999holes. Professional assembly and hand scrapping skills. The universal bi-rotary heads consisting of up head and low head can be turned to any desired angle and therefore vertical, horizontal and combined angle milling is available. The column is of a rugged box-type construction and its ground slide ways are wide to suppo....

This machine is of much heavier construction than the previous lathes listed. It features 1370mm over the bed, 1100mm over the carriage and 10,000mm between centres. This model incorporates reduction drive pinion and rin....

The automatic spraying machine compact 3 hy, guarantees the advantages of the automatic spraying process, while achieving a high flexibility level. The machine has a reciprocator with double arms sliding on high precisio....

Durma has redifned it s plasma cutting technology with the high-definition PL-C series. These high performance plasma machines are designed to cut a wide range of mild steel, stainless steel aluminium materials. The PLC ....

Standard machine design features on CNC benders include - Air conditioned electrical enclosure to maintain temperature and prolong system components - Electrical power filtering to stabilize incoming power supplies for a....

Haeger 824 OneTouch-5e Operation Fully Automatic Type Hydraulic Force 16,000 lbs. 72 kN Throat Depth 24 in. 610 mm Product Details 824 OneTouch-5e can be upgraded to Robotic Interface extra 28k 4 Station Automatic Lower Tool Changer An integrated cartridge with 4 tooling stations automatically retracts, indexes and positions up to 4 different tools in the lower tool holder. Maximum accessibility around the lower tool allows for parts with tall flanges to fit on the machine. 4 Station Automatic Upper Tool Changer 4 Insertion Stations and 4 Tool positions total of 8 pre-programmed posi....

L127 WMW NILES Centre Lathe with Deep Hole Drilling Unit Precision double V-slide shaft lathe with deep hole drilling capability, ideal for versatile machining applications. Key Features Deep Hole Drilling Unit capable o....

With more than 55 years of experience on lathe manufacturing, Victor Taichung s Vturn A-series lathes have upgraded the structure rigidity on the headstock, box slideways, turret, carriages and even the coolant and chip ....

The structural design of FS series are processed by the 3D finite element analysis FEA which makes sure the optimum structural patterns and stable cutting rigidity. With high quality cast iron frame, three axes boxway de....

Automatic Chain Sharpener Dinasaw model T-Rex, Australian made, any parts are readily available off the shelf, can be set up and run automatically, ideally suited to sharpening pack saw chains and those who require accur....