The LASERTAGMARK is a fully automated laser marking station designed to efficiently manage the marking of your plates in a single, safe, and synchronized workspace using your own data. The plates are marked in series automatically, meaning operator presence is unnecessary.

The TAGMARK LASER can be equipped with lasers of various power ratings, allowing for deeper marking or marking at higher speeds. The ytterbium-enhanced SIC Marking fiber laser features state-of-the-art technology that enables high-quality marking without damaging the piece and with a shorter cycle time.

After marking, the plates are transferred to a recovery tray, or, as an option, they can be removed via a gravity stacking system. It is also possible to mark individual parts if needed. Direct loading into the marking zone allows for marking plates of formats other than those predefined in the loading zone.

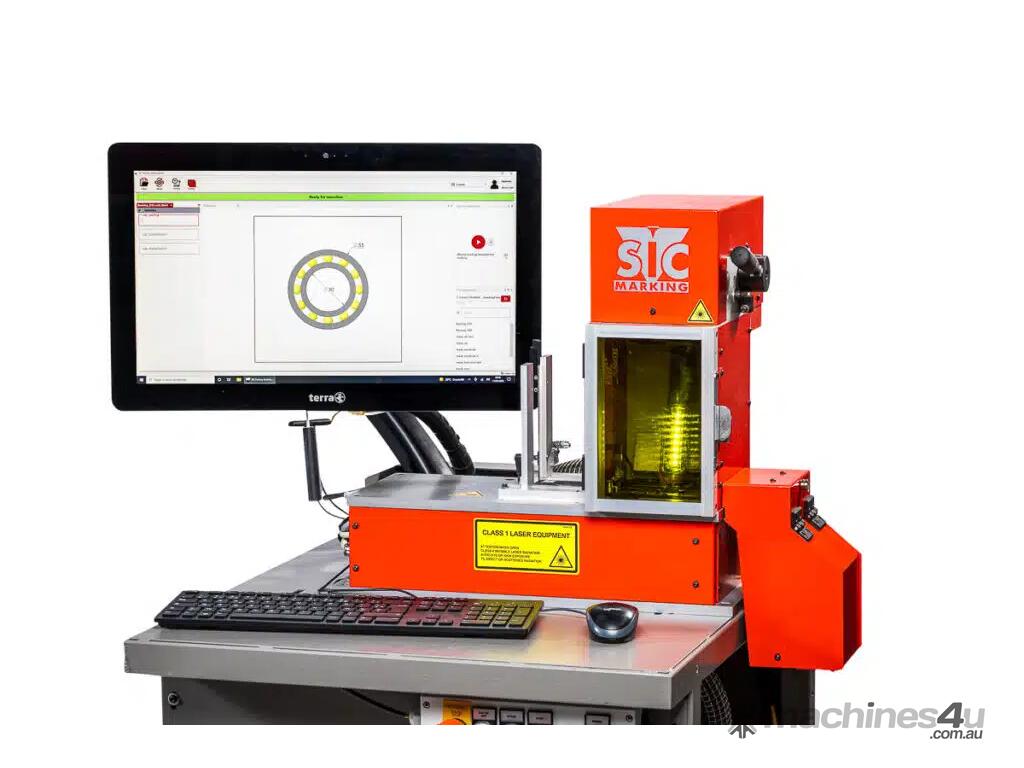

The new SFA (SIC Factory Automation) control software is compatible with your data management system, ensuring automatic data entry. This results in an optimized, configurable, and user-friendly human-machine interface (HMI).

The SFA software manages your marking needs based on your user profile—whether you are an operator, advanced user, or supervisor—with options for manual mode or database mode, compatible with your production management systems. The software can be customized beyond predefined cycles and also maintains your data history.

For more information, please see the attached PDF brochure.