Construction Upgrade:

Y-axis travel 600 mm, Victor’s new Vcenter-A85 and A110 have been launched to set up a new standard for C-frame type VMC. Supreme rigid and tough column enables the Z-axis acceleration 0.75G, the Vcenter-A85 and A110 presents rapid federate 42/42/42 m/min in all axes to minimize spindle noncutting time and to maximize spindle utilization.

With 10.4” color display included as standard on Victor’s package, Fanuc 21i-MB control has included AI contouring control which is capable of addressing look-ahead up to 80 blocks to offer optimal reliability with the highest level of machine integration. A strong machine with PLC developed in-house by highly experienced engineers, Vcenter-A85/A110 offer numerous safety features and maximizes the machine efficiency to meet the demands for most productions. For higher speed and precision, the control option Fanuc data server board can be installed to extend the memory length (Victor’s offer 320MB ATA card) to upgrade the data transfer rate. This controller can be upgraded to 18i-MB control which is capable of addressing 180 blocks to improve the surface finish. With the assistance of RISC board installed, the AI preview contouring can be upgraded to 600 blocks of HPCC (High Precision Contouring Control) or HP-nano-CC for even higher speed machining and minimal cutting time.The Fanuc conversational function “Manual Guide i” is included as standard in Victor’s NC package 21i/18i-MB to reduce the programming time.

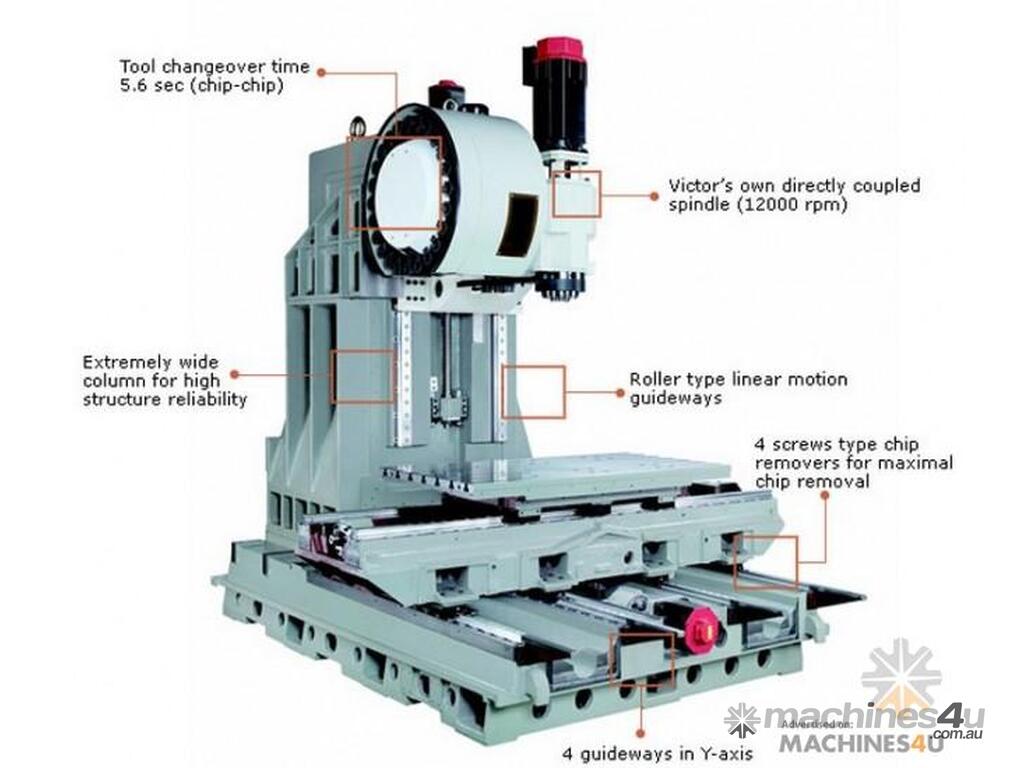

- Four linear motion guideways in Y-axis

- Z-axis acceleration 0.6g

- Rapid feed 36/36/36 m/min minimizes non-cutting time

- -coupled 12000rpm spindle assures part surface finish

- Supreme rigid column

- Easy access to working area and perfect sward and coolant disposal.