Inter-row cultivator for truffle born from the experience of the truffle growers combined with our 40 years experience in inter-row machines. The truffle growers need to hoeing the ground without mixing too much up the s....

FOR A STRICTLY LIMITED TIME, MERCURI TRADING IS ACCEPTING ALL REASONABLE OFFERS PRODUCT INFORMATION This pump is in great working condition. Made in Germany. Pump Make Hilge Type HYGIANA III 7-30 Motor 415V 30kW Inlet Si....

Gessner Economy Front Push Blade Product Features - 2500mm wide with reversible 3 4 bolt-on edge. - Mount designed to suit most brands of graders. - Blade fully boxed in with gusset moleboard. - Heavy-duty hydraulic cylinder. - Greased pins with hardened bushes. Blades can be fitted at Gessner Factory Toowoomba or can be shipped with detailed fitting instructions. For more information on the Grader Front Push Blade and other grader attachments provided by Gessner Industries, follow the link and give us a call. ....

Nitro 725RS Manure Spreader Tubeline Responding to market demand the NITRO Rancher Series was developed to ensure smaller operations get the same metering in a format tailored to them. NITRO RS spreaders are ideal for fa....

KSB Etanorm GC 150 x 200 SP 8 x 6 Siemens 3 15kW induction motor We have a very broad range of specialist chemical pumps, please see our store. Item is too heavy to post but we can assist with making freight arrangements....

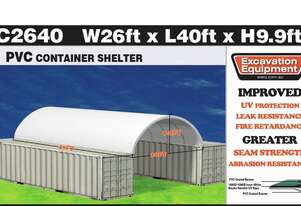

Model C2640 No End Wall Dimensions 26ft W x 40ft L x 9.9ft H from top of container OR 8m W x 12m L x 3m H from top of container High Strength Easy Assembly Inside Mounted Suited to Australian Weather Conditions Shipping ....

Moisture Manager Located at Burramine Vic By Sustain Ag 9m machine 26 units. 1 complete spare unit in box. Agtron Blockage monitor Knife points behind coulter gauge wheel. Groundhog closing tool seed tube and press wheel....

Fitted with Sink Toilet Extractor Fan Lights Toilet WELS Registration Number L07047 Efficiency Star Rating 4 Water Consumption Full Flush 4.5 L Half Flush 3.1 L Nominal Average Flush 3.4L Bathroom Tap Equipment WELS Regi....

Unused 4m Accommodation Pod Comes with Shower Toilet Sink Base for Bed Various Cupboards Storage Shipping Dimensions 3917mm Long x 2200mm Wide x 2360mm High Weight 1100Kgs Toilet WELS Registration Number L07047 Efficien....

Swift Agriculture proudly presents the Hawk 1000L Linkage Sprayer, a high-performance, reliable solution designed to meet the needs of Australian farmers. Built to endure tough conditions and simplify your spraying tasks....

ILGI AGRAGON XL 9M SPEED TILLER, S N 1508001, 2015 model, disc crumble roller, discs approx 75 , solid machine in good working order, Note torsion rubbers on front row appear worn however machine digs evenly when in the ....

Lovol TB754 ROPS Tractor Model TB754 Rops Comes with 4in1 Bucket featuring a convenient Euro mount quick-release system Versatile Pallet Forks 75HP ROPS Tractor that comes equipped with a front-end loader 4-cylinder 75h....

The engineers at SCAG challenge themselves with finding a way to shoehorn some of their most powerful zero turn technology into a much more compact footprint without cutting corners and the result is the Tiger Cat II lin....

The BL2 EX VT, designed for excavators from 8 to 14 t will mulch logs up to inches in diameter. It has a hydraulic piston motor with VT variable torque automatic displacement, significantly improving performance, increas....

1 Large Sliding Door 8 Sliding Windows Timber Look Flooring Adjustable Feet For Easy Levelling Approx Size When Opened 20ft x 20ft Approx Internal Floor Space 5.35m x 6.1m 32.5sqm Unit is Folded Ready for Transport Tran....

The TUFFASS SRH Series is a heavy-duty side delivery spreader designed specifically for spreading material under trees or vines. With its 1.1-meter narrow body, it is ideal for vineyards, macadamia and avocado orchards, and row crops. Built to withstand Australian conditions, the SRH Series is crafted from durable materials for long-lasting performance. Key Features Narrow Body Design Perfect for spreading in vineyard, crop bed, and orchard settings. Heavy-Duty Galvanized Steel Body Resists corrosion and ensures durability in tough Aussie conditions. Chain Floor and Spreading Mechani....

Lovol TE404 CAB Tractor Model LOVOL TE404 CAB Comes with a 40HP CAB Tractor that comes equipped with a front-end loader Versatile pallet forks 4 in 1 bucket featuring a convenient Euro mount quick-release system 4-cylin....

The new generation MGX Series range delivers class leading power and reliability while reducing environmental impact. With one of the largest cabs in its class, the premium MGX range offers unmatched operator comfort and visibility. Built for maximum power and torque output with intelligent technology, the MGX series is equipped to efficiently handle the most demanding jobs in the field or farm. Kubota s M100GX is engineered to deliver maximum power and torque output with outstanding economy and low emissions. Powered by a turbo charged, 100HP, 4 cylinder, CRS Kubota diesel engine an....